The Flooring Expert

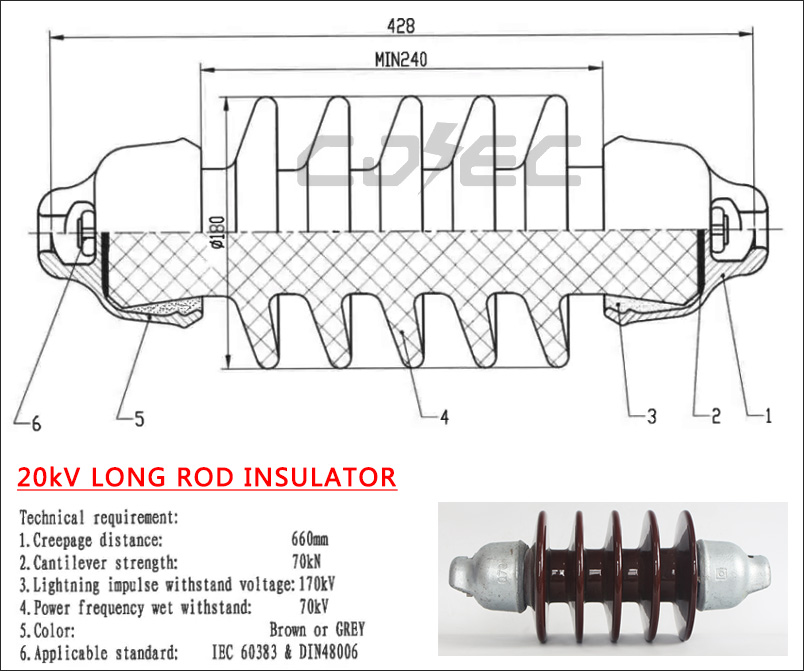

20KV 660mm Long Rod Suspension Porcelain Insulator Lp705390

| SI Class | L8/550 | L10/600 | L10/690 | L9/610 | L10/760 | L5/380 | L7/490 | L14/860 | |

| Creepage Distance,mm | 850 | 1000 | 1200 | 920 | 1200 | 500 | 700 | 1370 | |

| Tension Failing Strength,KN | 40 | 40 | 40 | 40 | 40 | 40 | 70 | 100 | |

| Main Dimensions | H | 550 | 600 | 690 | 610 | 760 | 380 | 490 | 860 |

| h | 382 | 430 | 510 | 362 | 500 | 340 | 440 | 775 | |

| D | 145 | 145 | 146 | 165 | 185 | 120 | 121 | 122 | |

| d1 | 21 | 22 | 23 | 24 | 25 | 11 | 16 | 19 | |

| Power frequency | Dry,kv | 140 | 140 | 180 | 115 | 180 | 100 | 120 | 200 |

| Flashover Voltage | Wet,kv | 120 | 120 | 150 | 90 | 150 | 90 | 100 | 170 |

| Impulse Flashover voltage,kv | 230 | 230 | 300 | 185 | 300 | 210 | 210 | 320 | |

Products Use

Each unit is constructed of a ceramic or glass disc with a metal cap and pin cemented to opposite sides. To make defective units obvious, glass units are designed so that an overvoltage causes a puncture arc through the glass instead of a flashover. The glass is heat-treated so it shatters, making the damaged unit visible. However the mechanical strength of the unit is unchanged, so the insulator string stays together.

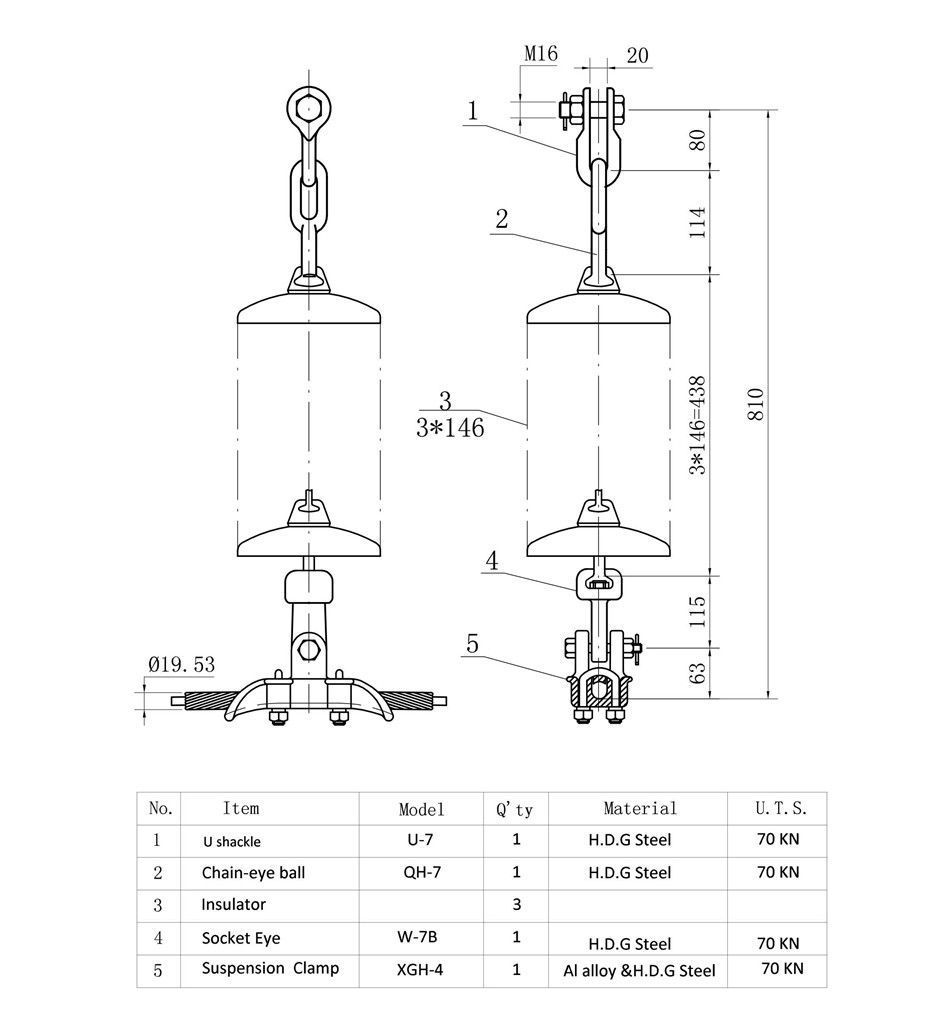

We use the tension clamp or strain clamp to connect the disc insulator with conduct wire together.

There are two link type according to usage in construction, one is tension type ,one is suspension type.

Standard suspension disc insulator units are 25 centimetres (9.8 in) in diameter and 15 cm (6 in) long, can support a load of 80-120 kN (18-27 klbf), have a dry flashover voltage of about 72 kV, and are rated at an operating voltage of 10-12 kV.[14] However, the flashover voltage of a string is less than the sum of its component discs, because the electric field is not distributed evenly across the string but is strongest at the disc nearest to the conductor, which flashes over first. Metal grading rings are sometimes added around the disc at the high voltage end, to reduce the electric field across that disc and improve flashover voltage.

Suspension insulators

Typical number of disc insulator units for standard line voltages

| LINE VOLTAGE(KV) | UNITS |

| 34.5 | 3 |

| 69 | 4 |

| 115 | 6 |

| 138 | 8 |

| 161 | 11 |

| 230 | 14 |

| 287 | 15 |

| 345 | 18 |

| 360 | 23 |

| 400 | 24 |

| 500 | 34 |

| 600 | 44 |

| 750 | 59 |

| 765 | 60 |

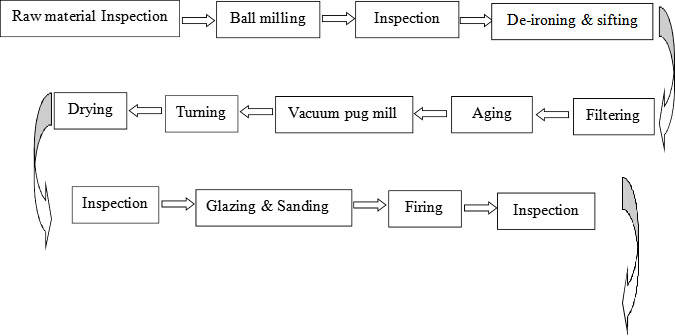

The production process

Our factory use the technological of wet process to produce.

Packaging

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..