The Flooring Expert

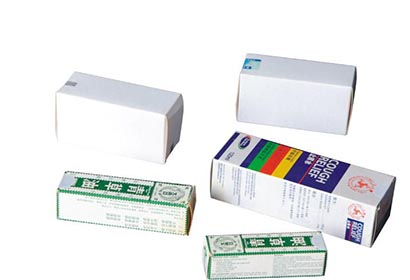

ALT-B Top Labeling Machine

lLabeling speed up to 150 pieces/minutes ( according to the length of label )

lHIM & PLC Control System which is easy to control

lSimple Straight Forward Operator Controls

lOn-Screen trouble description which is easy to solve

lStainless Frame

Open Frame design, easy to adjust and change the label

lVariable Speed with stepless motor

lLabel Count Down (for precise run of set number of labels) to Auto Shut Off

Stamping Coding Device (optional)

|

Speed |

80-150 pieces/minute |

|

Container Width |

20-100mm(Can be customized) |

|

Container Length |

20-200mm(Can be customized) |

|

Container Height |

15-150mm(Can be customized) |

|

Label Width |

15-130mm(Can be customized) |

|

Dimensions |

1600mm×600mm×1550 mm ( Length × Width × Height ) |

|

Weight |

180kg |

|

Electrical Requirements |

1000W,220v, 50-60HZ |

|

Working Direction |

Left → Right (or Right → Left) |

With the development of economy and the improvement of people’s living standards, every commodity in circulation needs to indicate the production date and shelf life and other relevant information. Packaging is the carrier of information, and labeling of commodities is the way to achieve it. A labeling machine is a machine that adds labels to packages or products. It not only has an aesthetic effect, but more importantly, it can track and manage product sales, especially in the pharmaceutical, food and other industries, if abnormalities occur, it can be accurate and timely To initiate a product recall mechanism.

The labeling machine is a device that pastes rolls of self-adhesive paper labels (paper or metal foil) on PCBs, products or specified packaging with high precision and accuracy to make product identification more beautiful. It is suitable for medicine, daily chemical, food, electronics and other fields. The labeling machine is an indispensable part of modern packaging.

At present, the types of labeling machines produced in my country are gradually increasing, and the technical level has also been greatly improved. It has shifted from the backward situation of manual and semi-automatic labeling to the pattern of automatic high-speed labeling machines occupying the vast market.

At the beginning of the working process, the box is fed to the labeling machine at a constant speed on the conveyor belt. The mechanical fixing device separates the boxes by a fixed distance and pushes the boxes along the conveyor belt. The mechanical system of the labeling machine includes a driving wheel, a labeling wheel, and a reel. The driving wheel drags the label tape intermittently, the label tape is pulled out from the reel, and the labeling wheel will press the label tape on the box after passing through the labeling wheel. An open-loop displacement control is used on the reel to maintain the tension of the label tape. Because the labels are closely connected to each other on the label tape, the label tape must constantly start and stop.

The label is attached to the box when the labeling wheel moves at the same speed as the box. When the conveyor belt reaches a certain position, the label belt drive wheel will accelerate to a speed that matches the conveyor belt, and after the label is attached, it will decelerate to a stop.

Since the label belt may slide, there is a registration mark on it to ensure that each label is placed correctly. The registration mark is read by a sensor. During the deceleration phase of the label tape, the drive wheel will readjust its position to correct any position errors on the label tape.

The main working mechanism of the labeling machine is composed of a label supply device, a label taking device, a printing device, a gluing device and an interlocking device.

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..