The Flooring Expert

CDS6250B/C Horizontal Lathe 82/105mm Spindle Bore Lathe

1. MACHINE PICTURES

2. SPECIFICATION

|

CDE&CDS SEREIS LATHE |

||||||||

|

ITEM |

UNIT |

CDE6240A |

CDE6250A |

CDE6266A |

CDS6250B |

CDS6250C |

CDS6266B |

CDS6266C |

|

Swing diameter over bed |

mm |

400 |

500 |

660 |

500 |

500 |

660 |

660 |

|

Swing diameter over carriage |

mm |

220 |

290 |

430 |

290 |

440 |

||

|

Swing diameter in gap |

mm |

700 |

760 |

910 |

760 |

870 |

||

|

Max workpiece length |

mm |

750/1000/1500/2000/3000 |

750/1000/1500/2000/3000 |

|||||

|

Spindle bore |

mm |

φ52 |

Φ82 |

Φ105 |

Φ82 |

Φ105 |

||

|

Spindle hole Taper |

|

Morse 6 |

D8 |

|||||

|

Spindle Speed |

rpm |

11-1400 |

26-2000 |

26-1700 |

||||

|

Tailstock Sleeve Diameter |

mm |

75 |

75 |

|||||

|

Tailstock sleeve travel |

mm |

150 |

150 |

|||||

|

Tailstock sleeve taper |

|

Morse 5 |

Morse 5 |

|||||

3. MACHINE DETAILS

|

HIGH RIGIDITY STRUCTURE DESIGN |

|

|

|

Because the bed adopts the whole casting shape, the bed guide adopts the mountain shape and the plane guide, which has the larger bearing section, therefore, has the good rigidity and the shock absorption, may guarantee the high precision cutting processing. |

|

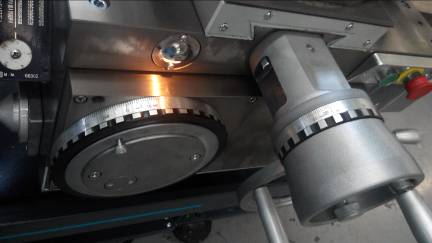

A CLUTCH OF SPINDLE BOX |

|

|

|

Spindle box USES mechanical friction piece of clutch: by manipulating, and don’t have to change the speed of the motor and stop the motor can realize of spindle speed, stop, reversing. |

|

HIGH RIGIDITY SPINDLE |

|

|

Type B is 82mm, Type C is 105mm spindle aperture. High rigidity spindle system with three point support for B type lathe. D8 spindle head is standard. |

|

HIGH RELIABILITY OF TOOL HOLDER |

|

|

High rigidity mechanical tool rest, high reliability and high repeat positioning accuracy. |

|

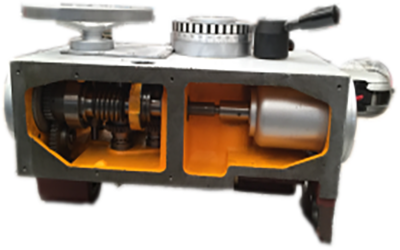

A TYPICAL SLIP BOARD BOX STRUCTURE |

|

|

|

Slip board box is equipped with fast moving device of the machine tool, a overload safety protection device; Longitudinal and cross control handle, the handle half nuts. The fashion simple calibration rings is unique. |

|

FAST VERTICAL AND HORIZONTAL DRIVE |

|

|

|

The slide box of the machine tool is equipped with a fast moving device, which can be moved to the desired position in both directions.With the light bar and lead screw interlock protection function, ensure the feed system normal trouble-free work. |

|

THE TYPE OF THREAD CAN BE CHANGED BY CHANGING THE HANDLE POSITION OF THE FEED BOX |

|

|

The type of thread can be changed by changing the handle position of the feed box. |

|

EXTERNAL OIL PUMP LUBRICATION, FORCED LUBRICATION OF SHAFT AND GEAR BOX, PROVIDE RELIABILITY. |

|

|

|

The machine’s headstock lubrication system, the latest upgrade to the external increased flow of oil pump lubrication system.Through the oil distributor, the headstock belt wheel shaft and gear box are forced lubricated to provide working reliability. |

4. WORKSHOP PICTURES

5. PACKING AND DELIVERY

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..