The Flooring Expert

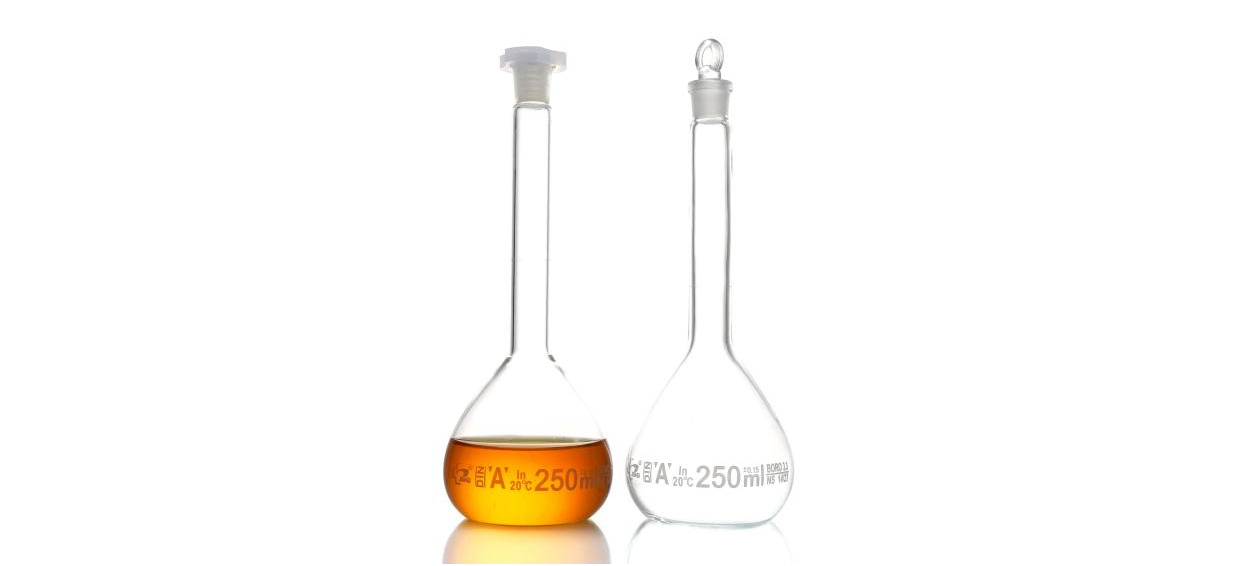

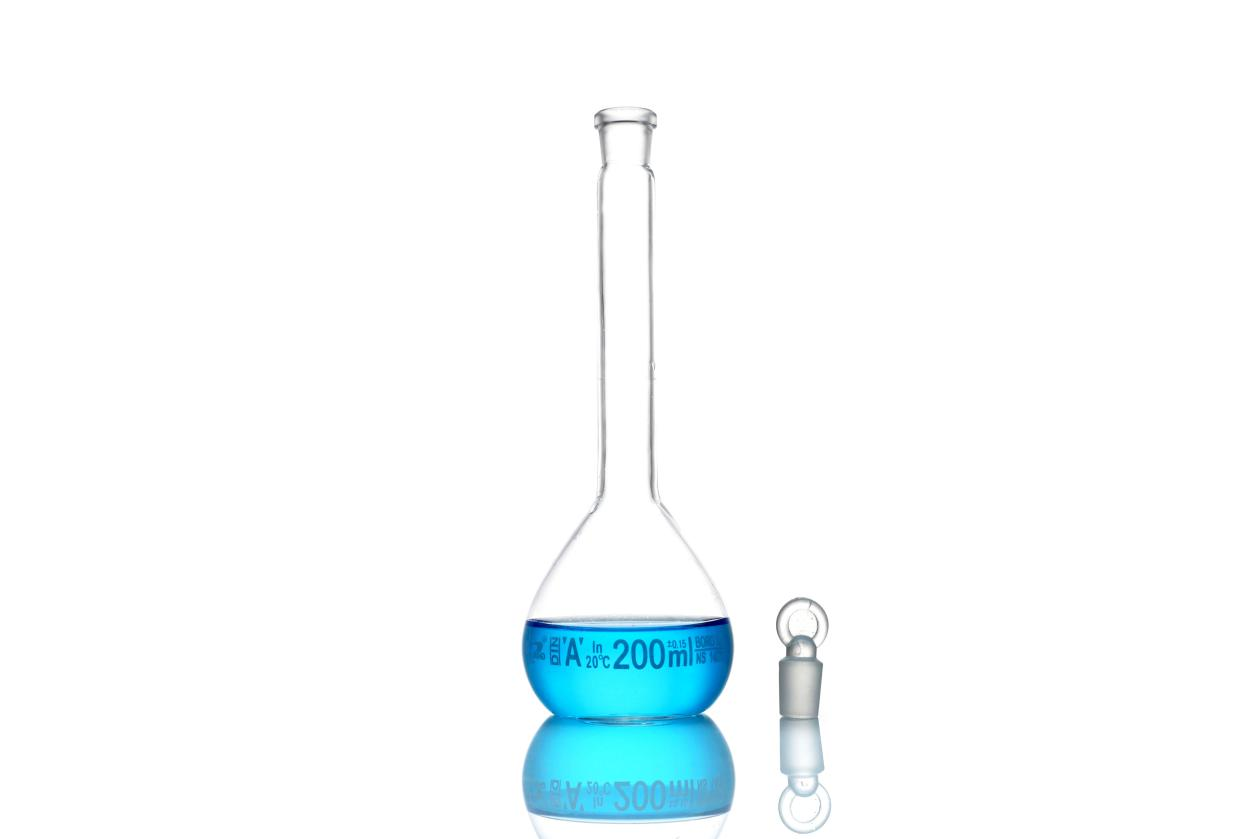

Clear and amber grade A Volumetric Flask With ground–in glass stopper or plastic stopper

Laboratory Glassware

Volumetric Flask

Volumetric Flask Introduction

A volumetric flask ( measuring flask or graduated flask) is a piece of laboratory glassware, a type of laboratory flask, calibrated to contain a precise volume at a particular temperature. Volumetric flasks are used for precise dilutions and preparation of standard solutions.

About Volumetric Flask

Product Specification

|

1621A |

Volumetric Flask grade A.,With ground–in glass stopper or plastic stopper, clear |

||

|

Capacity(ml) |

Capacity tolerance(±ml) |

Ground mouth |

Height(mm) |

|

5 |

0.02 |

39640 |

74 |

|

10 |

0.02 |

39640 |

90 |

|

25 |

0.03 |

39734 |

110 |

|

50 |

0.05 |

39734 |

140 |

|

100 |

0.1 |

39796 |

170 |

|

200 |

0.15 |

14/15 |

210 |

|

250 |

0.15 |

14/15 |

220 |

|

500 |

0.25 |

16/16 |

260 |

|

1000 |

0.4 |

19/17 |

310 |

|

2000 |

0.6 |

24/20 |

370 |

|

1622A |

Volumetric Flask amber,grade A,With ground–in glass stopper or plastic stopper |

||

|

Capacity(ml) |

Capacity tolerance(±ml) |

Ground mouth |

Height(mm) |

|

10 |

0.02 |

39640 |

90 |

|

25 |

0.03 |

39734 |

110 |

|

50 |

0.05 |

39734 |

140 |

|

100 |

0.1 |

39796 |

170 |

|

200 |

0.15 |

14/15 |

210 |

|

250 |

0.15 |

14/15 |

220 |

|

500 |

0.25 |

16/16 |

260 |

|

1000 |

0.4 |

19/17 |

310 |

Instructions

Before using the volumetric bottle, the following two checks are required.

1. The volume of the volumetric flask is consistent with what is needed.

2. Check that the cork is tight and does not leak.

Place water in the bottle near the marking line, plug the stopper tightly, and let it stand for 2 minutes. Check with the dry filter paper along the seam of the bottle to see that there is no water leakage. If it does not leak, turn the plug 180°, plug it tightly, invert it, and test for leaks in this direction. The tight stopper must be kept in a safe place. It is recommended to tie the rope to the bottle neck to prevent it from falling or being mixed with other stoppers.

Product Parameters

|

BOROSILICATE GLASS |

|

|

BORO3.3 |

|

| SiO2 Content | >80% |

| Strain Point | 520°C |

| Annealing Point | 560°C |

| Softening Point | 820°C |

| Refractive Index | 1.47 |

| Light Transmission(2mm) | 0.92 |

| Elastic Modulus | 67KNmm-2 |

| Tensile Strength | 40-120Nmm-2 |

| Glass stress Optical Coefficient | 3.8*10-6mm2/N |

| Processing Temperature(104dpas) | 1220°C |

| Linear Coefficient of Expansion(20-300°C) | 3.3*10-6K-1 |

| Density(20°C) | 2.23gcm-1 |

| Specific Heat | 0.9jg-1K-1 |

| Thermal Conductivity | 1.2Wm-1K-1 |

| Hydrolytic Resistance(ISO 719) | Grade 1 |

| Acid Resistance(ISO 185) | Grade 1 |

| Alkali Resistance(ISO 695) | Grade 2 |

| Thermal Shock Resistance Rod6*30mm | 300°C |

Scope Of Application

Medical field

Classroom equipment

Laboratory

Chemical industry