The Flooring Expert

Corrugated pipe line

Vertical air cooling PE double wall corrugated pipe line

Performance & Advantages

The corrugated pipe line is the 3rd generation of improved product of Suzhou . The output of the extruder and the production speed of the pipe are greatly increased by 20-40% compared with the previous product. Online belling can be achieved to ensure the performance of the formed corrugated pipe products. Adopts Siemens HMI system.

1. The newly designed closed molding machine adopts a special high-efficiency cooling system for forming aluminum modules, which greatly improves the cooling efficiency in the production of corrugated pipe products;

2. High-speed, high-output single-screw extrusion machine supporting a professional design of the corrugated pipe extrusion mould to achieve large-scale stable extrusion;

3. Good interchangeability of the module; the aluminum forming module uses LY12 high-quality alloy aviation aluminum material with copper content ≥ 5%, precision pressure casting process, high density material, no light pores, long-term use is not easily deformed. Can customize various module waveform schemes according to the user’s requirements;

4. Supporting automatic DWC cutter, computer control, accurate cutting position, stable running and easy to operate.

Main technical parameters

|

Type |

Pipe diameter |

HOPE output |

Max speed(m/min) |

Total power |

|

JWSBL-300 |

110-300 |

500 |

5.0 |

440 |

|

JWSBL-600 |

200-600 |

800 |

5.0 |

500 |

|

JWSBL-000 |

200-800 |

1000 |

3.0 |

680 |

|

JWSBL-1000 |

200-1000 |

1200 |

2.5 |

710 |

|

JWSBL-1200 |

800-1200 |

1400 |

1.5 |

800 |

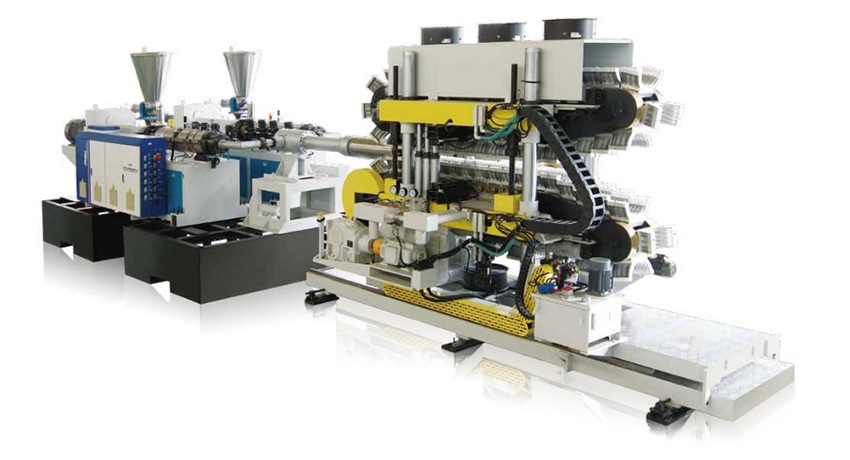

Horizontal water cooling PE double wall corrugated pipe line

newly developed horizontal double-wall corrugated production line is a second-generation horizontal pressure water cooling production line, which is independently developed on the basis of domestic and international advanced technologies. It has more than ten invention patents.

● There are a variety of types of extruder to choose, which can achieve the production of various HDPE, PP pipe, also can meet the production demand of single-wall corrugated pipe.

● Sizing sleeve is made of aluminum alloy, and the surface is wear-resistant. The tube waveform can be calculated by special software program, and the ring stiffness can be obtained at the same weight.

● The sliding base of forming machine is geared and equipped with large size needle roller bearing, which improves the bearing capacity of the sliding base. More stable operation, longer life.

● Production line is fixed center height, and there is no need to adjust again when changing model.

● Common production line modules with different specifications. Quick unloading module design makes module loading and unloading convenient and fast. The unique internal module cooling design enables the cooling water to flow rapidly. internal module realizes the rapid cooling and shaping of pipes. The main drive is driven by a two-speed motor, which can realize stable and accurate operation.

● Using advanced PLC and color LCD control system, which can be adjusted by single machine, linkage of all lines, simple operation, stable and reliable production, high degree of automation, automatic fault alarm.

Main technical parameter

|

Type |

Pipe Size |

Production Speed |

Total Power |

Product line length and width |

|

JWBW-150 |

ID40-150 |

Max 15 |

270 |

28×4.5 |

|

JWBW-300 |

ID100 – 300 |

Max 5 |

400 |

30×6 |

|

JWBW-600 |

ID100 – 600 |

Max 4.2 |

600 |

34×6 |

|

JWBW-800 |

ID200-800 |

Max 4.2 |

750 |

38×8 |

|

JWBW-1000 |

ID300-1000 |

Max 29 |

795 |

38×8.5 |

|

JWBW-1200 |

ID4OO-12OO |

Max 2 |

890 |

38×9 |

|

JWBW-1500 |

ID600- 1500 |

Max 1.2 |

1110 |

42×9.5 |

PVC double wall corrugated Pipe Production Line

Performance & Advantages

In order to meet market, Suzhou based on years of experience, independent research and develop of conical twin-screw extruder series FRPP / PVC DWC pipe line, has the following characteristics:

1. The overall energy consumption of the production line is low, the conveyor efficiency of the conical twin screw extruder is higher than that of the single screw extruder, and the installed power is less than the single screw extruder.

2. The powder material can be extrusion directly, use raw material + calcium powder formula, reduce the cost and improve the pipe ring stiffness.

3. The extruder has a vacuum device to overcome the problem of air bubbles inside and outside the pipe due to the moisture content in the raw material.

Main technical parameter

|

Type |

Pipe diameter |

PVC Output |

Frpp Ouput |

Max speed(m/min) |

|

JWSBL-300 |

110-300 |

450 |

400 |

4.0 |

|

JWSBL-600 |

200-600 |

800 |

800 |

3.0 |

|

JWSBL-800 |

200-600 |

1200 |

1000 |

3.0 |

|

JWSBL-1000 |

200-1000 |

1300 |

1200 |

2.5 |

|

JWSBL-1200 |

800-1200 |

1400 |

1400 |

1.5 |

Parallel Twin-screw Extruder HDPE/PP Double-wall Corrugated Pipe Production Line

Performance & Advantages

Suzhou introduced European advanced technology and newly developed paral

lel-parallel twin screw extruder HDPE/PP DWC pipe line, which has the following characteristics:

1. Adopt two parallel twin-screw extruders, and the mixing effect is excellent. It is possible to use both powdered and granular raw materials at the same time without the need for granulation and low raw material costs;

2. The extruder is equipped with a side feeding system, which can adjust the calcium powder filling ratio at any time online, and the formula exchange is convenient;

3. Extruder has vacuum vents. To make the inner and outer walls of the pipe dense and smooth without bubbles;

4. The screw & barrel are building block type. maintenance and replacement easily.

Main technical parameters

|

Type |

Pipe diameter |

HDPE output |

Max speed(m/min) |

Total power |

|

JWSBL-600 |

200-600 |

800 |

5.0 |

500 |

|

JWSBL-1000 |

200-1000 |

1200 |

2.5 |

710 |

|

JWSBL-1200 |

800-1200 |

1400 |

1.5 |

800 |

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..