The Flooring Expert

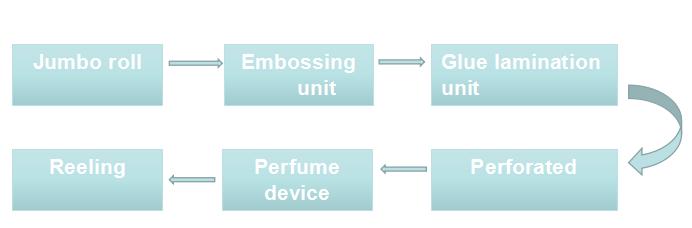

F-P350 Non-stop Converting Line for Toilet Roll and Kitchen Towel

Toilet paper full embossing roller slitting rewinding machine is to perforate and cut the raw paper into various sizes according to the requested. The finished product is neat, in good order and with equality tension. It has the feature of compact structure, easy and stable operation, less electricity consumption and covers a small area. The highest production speed is 200-350M/min.

It has HMI, Chinese-English switch; synchronous frequency conversion drive;integration of mechanics, electrics and photo. It is equipped with whole trouble information. It can detect and adjust every action of the rewinder automatically to keep the rewinder in optimal situation.For example:There is a web tension system in the line,It can control speed according to the tension of web so it can adapt different type of jumbo roll.So it is the best choice to produce top-grade bathroom tissue and kitchen towel for paper company.

1. Gluing blade system is used in F-20 tail sealer: the system perfectly improves the sealing of tissue rolls and reduces glue waste, making machine easy to clean and maintain.

2. The equipment has the function of reel breaking and reel end detection, equipped with automatic alarm, decelerating and stop device.

3. Accumulator: When accumulator is overloaded or undersupplied, it will automatically stop.

4. It uses Programmable Control System, frequency converter to adjust speed, electronic brake and Human Machine Interface. There is mechanical speed adjustment for unwinding back stands which is based on the stretching and tension of the raw paper. Enable the equipment to operate under optimal condition

Technical Parameter

| Machine Model | 2800/2900/3600/4000/4300 |

| Width of Parent Roll | 2750/2850/3550/3950/4250(mm) |

| Working Speed | 350m/min |

| Dia. of Finished Roll | 90-150 |

| Dia. of Parent Rall | 1500, 2000, 2500, 3000 |

| Inner Dia. of Parent Roll’s Core | 76.2 (customized) |

| Perforation Pitch | 120mm (Adiustable, other size please specify) |

| Programmable Controller | PLC computer programming |

| Count Mode of Paper Roll | by the diameter or sheets amount |

| Glue Laminator | point to point,decorative embossing |

| Unwinder | 1-4 ply(customized) |

| Motive Power | 90-150 KW |

Details

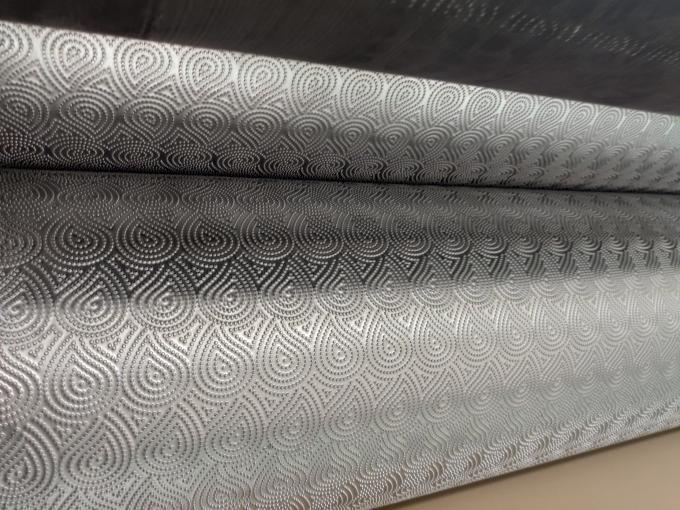

Full embossing device

This embossing unit can engrave the pattern without color, the diameter of roller is 240mm, and the pattern is engraved by computer, it it very clear and regular.

Jumbo roll stand

Independent wall-type jumbo roll stand, structure is simpler and stronger, easy to clean. It is controlled by the independent frequency motor, and the tension is tracked by the encoder.

Glue lamination device

This glue lamination unit can add colors, but one glue lamination can only engrave one kind of pattern, the diameter of the embossing rollers are 394 mm. And the pattern is engraved by computer, it it very clear and regular. Pattern can be any logo, words, flowers,etc

Real machine model:

1 rewinding unit + 1 glue lamination unit + 2 full embossing units + 2 jumbo roll stands

Company Information

LIUZHOU FEXIK INTELLIGENT EQUIPMENT CO.,LTD is a professional manufacturer and exporter of tissue paper machinery in China, dedicating to whole complete automatic household tissue production line equipment from raw paper to finished package. Our products include toilet rolls,packing machine,kitchen towel packaging machine,facial tissue packing machine,toilet paper and kitchen towel production line,facial tissue and hand towel production line,which are exported to middle east Asian countries,Americas,Europe and Africa.

FEXIK company covers an area of 20,000 square meters, which is divided into official area, parts processing centre, spare parts assembly line, whole machine assembly center and finished machine testing center.

We have been committing to research and innovation for many years.We have a team of professional designers, so that all the machines of FEXIK are independently researched and designed. Our company has a number of national invention patents,and have passed the international certification CE, ISO9001. These innovations are dedicated predominantly to the tissue paper converting and packaging machinery. We can design a whole line solution for clients from rewinding, cutting, packaging, conveying and stacking–CAD.Product design is able to adapt to the global market packaging. Packaging design can be customized according to clients’ requirement.Improve product technical performance to promote production stability, thereby our machines can reduce product loss and energy consumption. Efficient and orderly production process and numerous high-precision processing equipment can ensure that products are delivered on time with quality and quantity.

We uphold the principle of quality first, customer supreme, scientifically management, striving for famous brand. We export tissue paper machinery around the world, not only can provide high quality products for customers, but also can provide customized products. FEXIK company will continue to enhance its core competitiveness, optimize product structure, improve management mechanisms and actively introduce technical personnel. With strong technical strength. We continually commit to design, develop, and promote our products, which not only can provide customers with high-quality products, but also provide with customized products.

Certifications

We focus on research and innovation for many years. With full independent intellectual property rights, FEXIK Machinery has passed international certification I S O 9 0 0 1 and many national invention patents. We have full independent intellectual property rights.

Exhibition

As an exhibitor, we are so glad to have the opportunities to showcase our toilet tissue paper roll and kitchen towel roll packaging machine and other household paper production line machines and technology to a broad audience of tissue industry professionals from all over the world.

Our Services

1. One year maintenance service. Damage spare part can be exchanged from our company directly(excluding the easy damaged goods).

2. After one year, we will continue to assist you both on technical problem and the quality level for long-term.

4. We offer the DVD for machine operation and install, the DVD and all manual shipped together with the machines.

5. We welcome you to offer us the paper sample, we can design the machine in OEM.

Packing And Shipping

FAQ:

1. Are you trading company or manufacturer?

We are a factory, welcome to our factory.

2. Do you provide design?

We can design a whole line solution for clients from rewinding, cutting, packaging, conveying and stacking–CAD, provide the best solutions.

3. How much area the whole production line needs?

The best way is telling us your workshop area, then we will draw a draft for you to ensure the rational use of your space.

4. Do you offer guarantee for the machine?

Yes, we offer 12 months guarantee for the machine and training how to install and use the machine, If the customer needs, we can also provide overseas after-sales service.

5. Can we use the bags we provide for the machine?

We support sample testing.

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..