The Flooring Expert

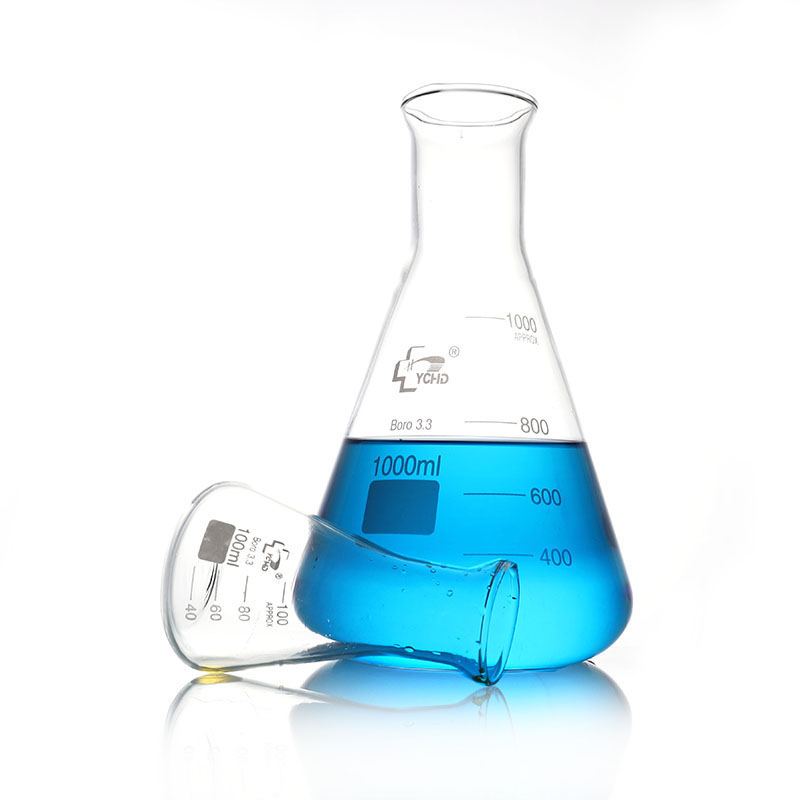

Laboratory equipment high temperature resistant glass conical flask Erlenmeyer flask

Laboratory Glassware

Conical Flask

Conical Flask Introduction

A conical flask/erlenmeyer flask is used as a reaction vessel for preparing a solution, a dissolved substance, and a relatively large amount of a substance at normal temperature or under heating.

About Conical Flask

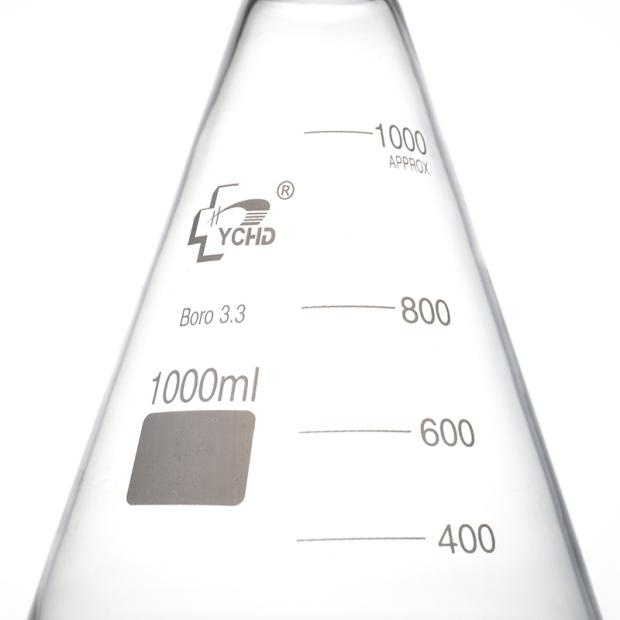

Product Details

Borosilicate glass has excellent chemical and physical properties.The linear expansion cofficient of the primary hydrolyzable glass is 3.3 for applications requiring excellent chemical resistance and thermal resistance (including thermal shock resistance), as well as high mechanical stability. It is a typical glass for chemical equipment.

Product Specification

The dimensions are all measured by hand, so there may be some errors. Please contact us for the specific freight.

|

1120 |

Conical flask, (Erlenmeyer Flask), Wide neck, with graduations | ||

|

Capacity |

O.D. of neck |

O.D. of bulb |

Height |

|

25 |

32 |

42 |

70 |

|

50 |

34 |

51 |

85 |

|

100 |

34 |

64 |

105 |

|

200 |

50 |

79 |

131 |

|

250 |

50 |

85 |

140 |

|

300 |

50 |

87 |

156 |

|

500 |

50 |

105 |

175 |

|

1000 |

50 |

131 |

220 |

|

2000 |

72 |

153 |

280 |

|

3000 |

106 |

190 |

285 |

|

1121 |

Conical flask, (Erlenmeyer Flask), Narrow neck, with graduations | ||

|

Capacity |

O.D. of neck |

O.D. of bulb |

Height |

|

5 |

14 |

25 |

50 |

|

10 |

16 |

30 |

55 |

|

25 |

22 |

42 |

75 |

|

50 |

22 |

51 |

90 |

|

100 |

22 |

64 |

105 |

|

150 |

28 |

71 |

120 |

|

200 |

34 |

79 |

135 |

|

250 |

34 |

85 |

145 |

|

300 |

34 |

87 |

160 |

|

500 |

34 |

105 |

180 |

|

1000 |

42 |

131 |

220 |

|

2000 |

50 |

166 |

280 |

|

3000 |

50 |

187 |

310 |

|

5000 |

50 |

220 |

365 |

|

10000 |

76 |

295 |

435 |

|

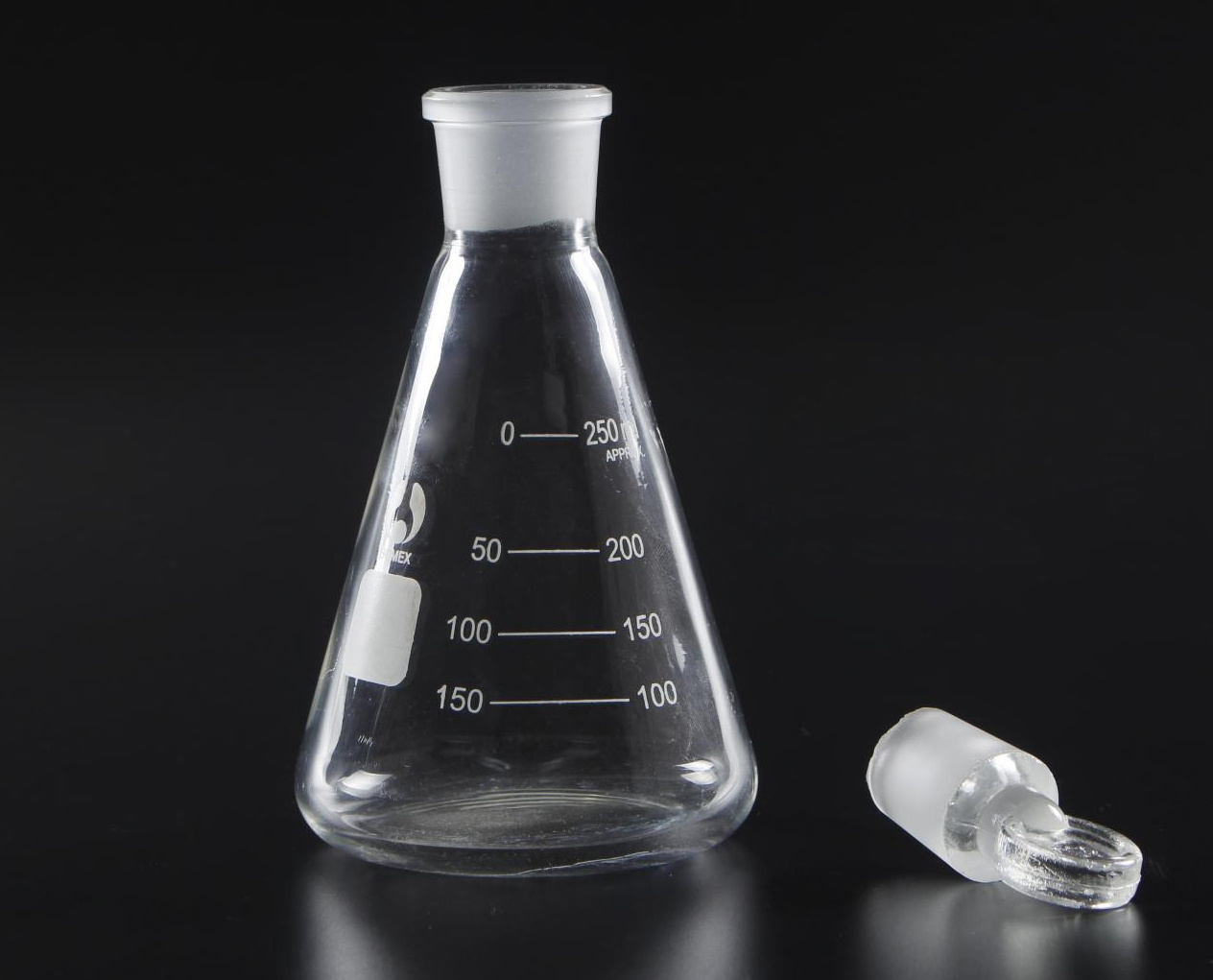

1122 |

Conical flask, With ground-in glass stopper | |

|

Capacity (ml) |

O.D.of bulb (mm) |

Height (mm) |

|

50 |

50 |

90 |

|

100 |

60 |

108 |

|

250 |

83 |

140 |

|

500 |

98 |

185 |

|

1000 |

130 |

230 |

|

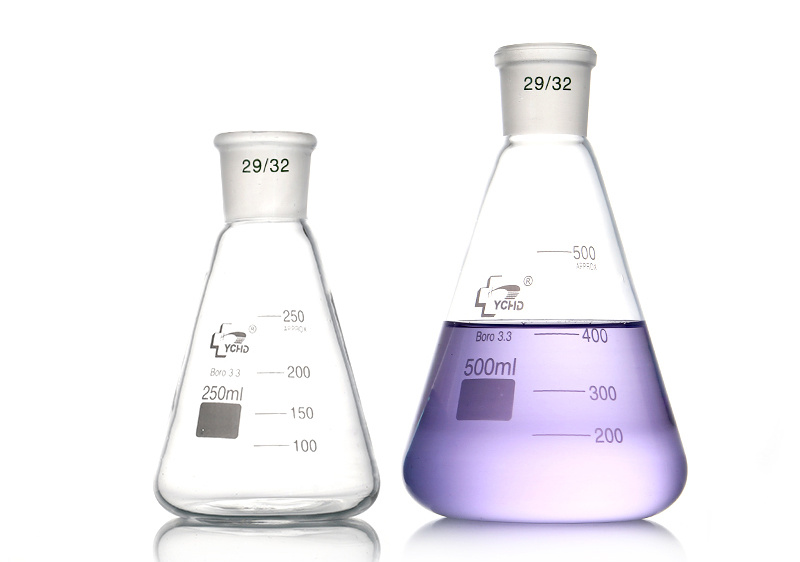

5009 |

Conical Flask Standard ground mouth |

||

|

Capacity(ml) |

Ground mouth |

O.D.of bottle(mm) |

Height(mm) |

|

5 |

10/19 |

25 |

50 |

|

5 |

14/23 |

25 |

50 |

|

10 |

10/19 |

32 |

60 |

|

10 |

14/23 |

32 |

60 |

|

10 |

19/26 |

32 |

60 |

|

25 |

10/19 |

42 |

65 |

|

25 |

14/23 |

42 |

70 |

|

25 |

19/26 |

42 |

75 |

|

50 |

14/23 |

51 |

85 |

|

50 |

19/26 |

51 |

85 |

|

50 |

24/29 |

51 |

90 |

|

100 |

14/23 |

64 |

105 |

|

100 |

19/26 |

64 |

105 |

|

100 |

24/29 |

64 |

105 |

|

100 |

29/32 |

64 |

105 |

|

150 |

19/26 |

71 |

115 |

|

150 |

24/29 |

71 |

115 |

|

250 |

19/26 |

85 |

135 |

|

250 |

24/29 |

85 |

135 |

|

250 |

29/32 |

85 |

128 |

|

250 |

34/35 |

85 |

128 |

|

500 |

19/26 |

105 |

170 |

|

500 |

24/29 |

105 |

170 |

|

500 |

29/32 |

105 |

165 |

|

500 |

34/35 |

105 |

160 |

|

1000 |

24/29 |

131 |

210 |

|

1000 |

29/32 |

131 |

210 |

|

1000 |

34/35 |

131 |

210 |

|

2000 |

29/35 |

166 |

275 |

|

2000 |

34/35 |

166 |

275 |

Product Parameters

|

BOROSILICATE GLASS |

|

|

BORO3.3 |

|

| SiO2 Content | >80% |

| Strain Point | 520°C |

| Annealing Point | 560°C |

| Softening Point | 820°C |

| Refractive Index | 1.47 |

| Light Transmission(2mm) | 0.92 |

| Elastic Modulus | 67KNmm-2 |

| Tensile Strength | 40-120Nmm-2 |

| Glass stress Optical Coefficient | 3.8*10-6mm2/N |

| Processing Temperature(104dpas) | 1220°C |

| Linear Coefficient of Expansion(20-300°C) | 3.3*10-6K-1 |

| Density(20°C) | 2.23gcm-1 |

| Specific Heat | 0.9jg-1K-1 |

| Thermal Conductivity | 1.2Wm-1K-1 |

| Hydrolytic Resistance(ISO 719) | Grade 1 |

| Acid Resistance(ISO 185) | Grade 1 |

| Alkali Resistance(ISO 695) | Grade 2 |

| Thermal Shock Resistance Rod6*30mm | 300°C |

Scope Of Application

Medical field

Classroom equipment

Laboratory

Chemical industry

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..