The Flooring Expert

PP Plastic Faced Plywood

Description:

| Product Name | PP Plastic Faced Plywood |

| Size (mm) | 610x2440mm/1220x2440mm/1250x2500mm |

| Thickness(mm) | 15/18mm |

| Core Wood Type | Combi Core/Full Eucalyptus |

| Glue Type | Melamine/Phenolic |

| Veneer Treatment | 2 times hot press/2 times sanding |

| Density (kg/m3) | 550-630 |

| Moisture Content | 8%-12% |

| Edges Treatment | Sealed by Waterproof Painting |

| Use Time | 30-50 times depends on the glue type |

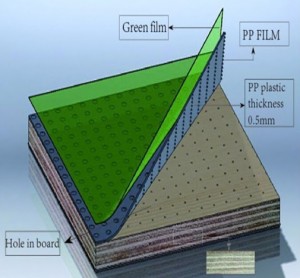

PP Plastic Faced Plywood, full name is polypropylene coating plywood. Because of the physical property of plastic polypropylene, PP Plastic Coating Plywood is Wear-resistant, durable, waterproof and hardness.

PP Plastic Coated Plywood is made by hardwood veneers hot press and coating with corrosion resistance 0.5mm thickness polypropylene on both sides, the color of polypropylene can be green, yellow, blue and red, etc.

PP Plastic Plywood physical and mechanical properties are very good compare to the traditional film faced plywood:

• High strength

• High wear resistance

• Waterproof performance

• Excellent longitudinal and transverse bending force

• Reusability (more than 30 times)

The quality of the formwork on the construction site not only requires a large number of uses but also requires an easy operation.

In the conventional formwork system, the use frequency and strength of the wooden formwork are relatively poor, the steel formwork is too heavy, it is not easy for workers to operate and construct on jobsite, the aluminum formwork is expensive, and the on-site cutting is difficult. For projects with more than 200 times, aluminum formwork is not suitable.

The emergence of PP plastic plywood formwork solves all the above problems. This PP plastic template has no warpage, no deformation, no cracking, good water resistance, high turnover rate, is easy to demold after use, and is easier in the construction of high-rise buildings and bridges.

The specific performance is as follows:

Use times: It can be reused more than 30 times under proper storage.

Smooth concrete finished: The surface of the pouring object is smooth and beautiful, minus the secondary plastering process of the wall, directly reducing the construction period.

Corrosion resistance: It is resistant to acid and alkali, and is hardly corroded by concrete.

Good thermal insulation: it is conducive to winter construction and can be used to transform flat formwork.

Good construction performance: nails, saws, drills, and other properties are better than bamboo plywood, small steel plates, and can be divided into various shapes according to construction needs.

|

Property |

EN |

Unit |

Standard value |

Average Value |

|

Moisture content |

EN322 |

% |

8-12 |

7.50 |

|

Number of plies |

- |

Ply |

- |

13 |

|

Density |

EN322 |

KG/M3 |

550-630 |

580 |

|

Longitudinal Modulus of elasticity |

EN310 |

Mpa |

≥6000 |

10050 |

|

Lateral Modulus of elasticity |

EN310 |

Mpa |

≥4500 |

7450 |

|

Longitudinal Strength Bending N/mm2 |

EN310 |

Mpa |

≥30 |

42.1 |

|

Lateral Strength Bending N/mm2 |

EN310 |

Mpa |

≥25 |

38.2 |