The Flooring Expert

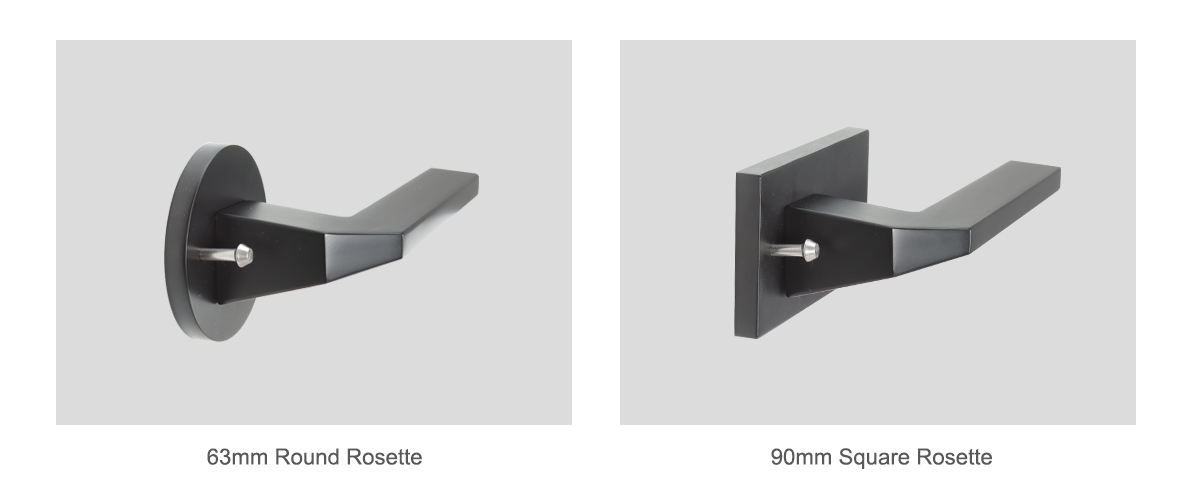

Privacy Door Handle Lock For Bathroom Doors

Product Feature

Raw Material:

YALIS door handles adopt 3# zinc alloy which contains about 0.042% copper, can increase the hardness of the door handles.

Electroplating Technique:

YALIS adopts high temperature electroplating, about from 120℃ to 130℃. It can provide better finish and longer service life for door handles.

Electroplating Layer:

YALIS door handles are mostly with 7-8 electroplating layers.

Polishing Technique:

YALIS sets up a clear standard for inspection, can not accept the blister products, waves products and out of shape products.

Die-casting Technique:

Adopting 160T-200T die-casting machine and the opening time of die-casting is 6s, which makes the density of zinc alloy door handle high.

Life Cycle Of The Spring:

Life cycle for euro standard is at least 200,000 times.

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..