The Flooring Expert

Single Shaft Shredder

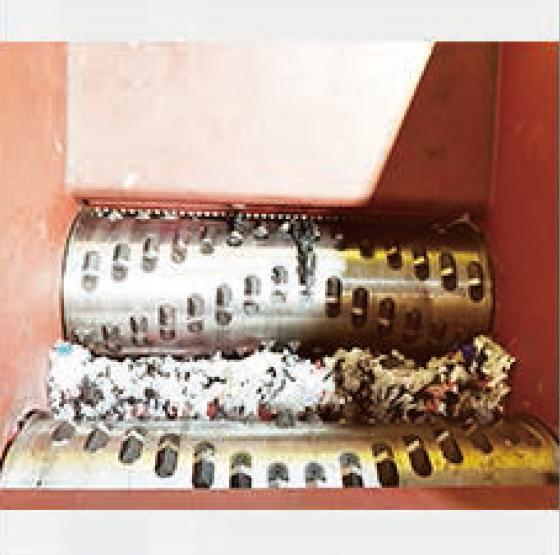

Shredding Chamber

There is specially position equipments designed to locate the main shaft and the sliding components positioned in the middle of shaft will even the raw material. So the raw material feeded will stack in the middle of the shredding chamber so the hydraulic pusher is not needed and every knives on the main shaft will cut the raw material automatically and evenly. The distance between the screen and knives will be positioned well so the raw materiall will not return back and the wearing of the main shaft will be lowered down, the capacity will be increased. The module type wearing plate is installed inside the shredding chamber will make sure the housing of shredder will not be weared out.

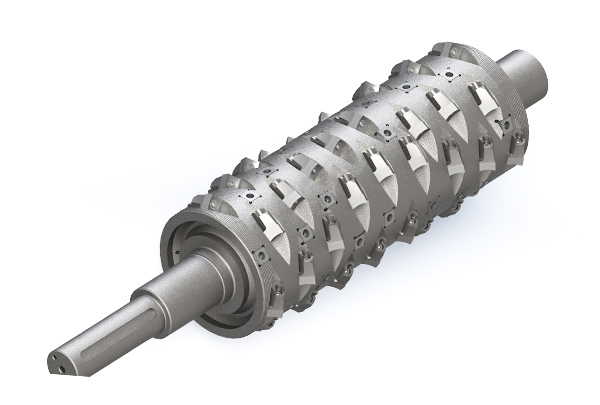

H type knives

The Knives are arranged as S screw type or V type allocation on the roller. The knives and seat are fastened to the main shaft by screws so it can be dismantled easily. The dynamic balance moment of main shaft can be assured and the vibration and the noise of shredder will be lowered, the efficiency will be better.

.png)

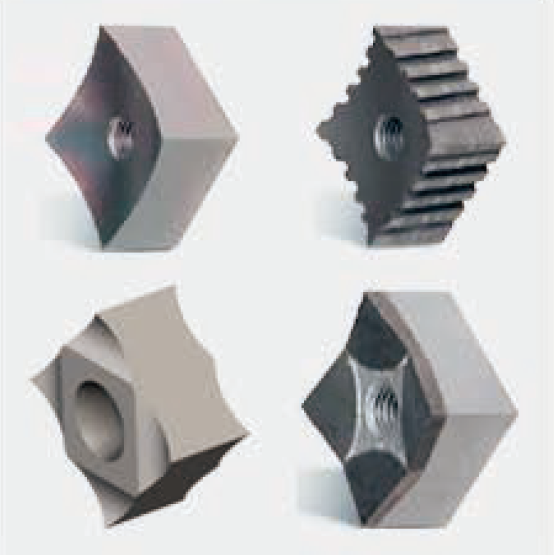

M type hardened type Knives

The wearing proof material is welded to the surface of main shaft, the seat of knives can be movable or fixed and welded type. This type of knives are used widely for PP film, PET bottle, woven bag, cans, MSW, plastic pipe, fabric, tape, etc.

V type high efficiency Knives.

The surface of roller is machined as screw type groove. The anti-wearing function is high, the allocation of the knives is close, the capacity is big and the efficiency is high. The Hard plastic, paper, wood, textile, straw and hollow barrel, etc.

Knives

The material of Knives can be alloy steel DC53 and HARDOX550 wearing material depending on the character of the raw material. When the shredder is used for wearing material like fiber, textile, glass fabric, MSW, etc, the HARDOX is used.

SEAT of Knives

The movable seat of knives is installed according to the pin on the groove and locked by the bolts. So the accuracy is high and can be used for heavy duty, the knives are easy to replace for the maintenace.

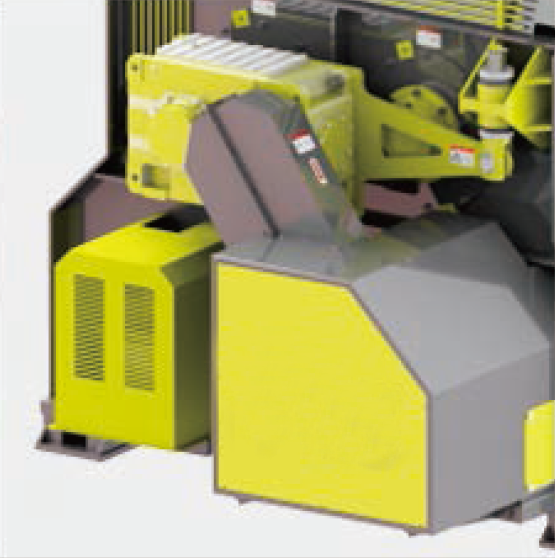

Buffer for the vibration

When shred the hard material, the shock of the roller will be high as heavy duty, to avoid the contact of knives and the head of the roller is protected from the over pressure, so the soft material as buffer is necessary, and the vibration level socket is installed, when the vibration is too serious, the automatic reverse of the shredder will happen or the shredder will be stopped automatically.

Buffer for the vibration

When shred the hard material, the shock of the roller will be high as heavy duty, to avoid the contact of knives and the head of the roller is protected from the over pressure, so the soft material as buffer is necessary, and the vibration level socket is installed, when the vibration is too serious, the automatic reverse of the shredder will happen or the shredder will be stopped automatically.

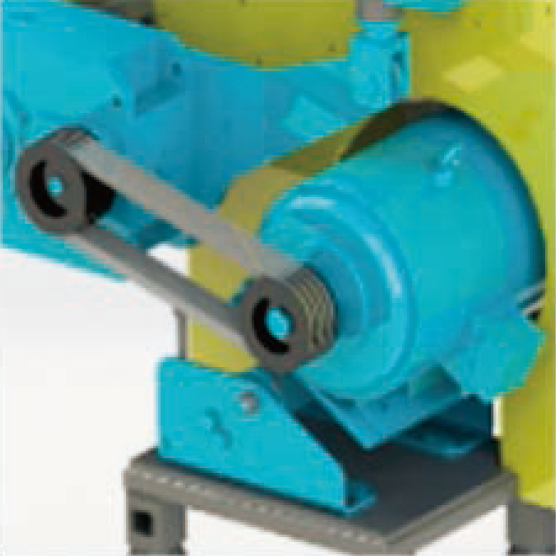

Hydraulic Coupling

The hydraulic oil is fitted into the coupling as the medium to transmit the moment. So the change of the duty of the shredder will be smooth and stepless no matter the torque or the rotation speed. When the antiforce is big, the speed is lowered to increase the torque so the operation of the shredder will be smooth. And the turbo is connected with the wheel of the pump with the soft coupling so the service time is extended.

| MODEL | SSD1000 | SSD1500 | SSD2000 |

| Overall dimension (L×W×H) | 3950×2580×4115mm | 4500×3000×4115mm | 5025×3020×4500mm |

| Feeding Height | 3300mm | 3300mm | 3300mm |

| Shredding Chamber | 1730×1020mm | 2230×1550mm | 2750×2050mm |

| N.W | 17.5~18.2 T | 21~22.5 T | 35.7~36.5 T |

| oil tank | 400L | 750L | 1000L |

| hydraulic pressure | 30MPa | 32MPa | 35MPa |

| drive type | Electric/Hydraulic | Electric/Hydraulic | Electric/Hydraulic |

| output of motor | 2×55 / 2×75Kw | 2×90 / 2×110Kw | 2×132 / 2×160Kw |

| Control System | PLC+MODBUS Communication | PLC+MODBUS Communication | PLC+MODBUS Communication |

| Roller qty | 2 | 2 | 2 |

| speed of main shaft | 160-200/ 160-250 | 160-200/ 160-250 | 160-200/ 160-250 |

| qty of knives | 90 | 220 | 325 |

| discharge size | 6-100mm | 6-100mm | 6-100mm |

| Capacity | 6-7 T/H | 13-15T/H | 22-25T/H |

| Model | BEKEN-SSS-80120 | BEKEN-VSS-60150 |

| Overall Size (L*W*H) | 3600x1920x2290 | 3380*2410*3200 |

| Shredding Area L*W(mm) | 2190x1120mm | 1530*1490 |

| Cutter Rotor Diameter(mm) | Φ870mm | Φ602mm |

| Screen mesh(mm) | 90mm | 130mm |

| Shaft Speed(rpm) | 5-30rpm | 5-30rpm |

| Cutter Qty(pcs) | 23 pcs | 155 pcs |

| Cutter Thickness(mm) | 75mm | 30-50MM Optional |

| Motor(kw) | 160KW | 110+7.5 |

| Particles size after shredding | 90mm | 30-50MM Optional |

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..