The Flooring Expert

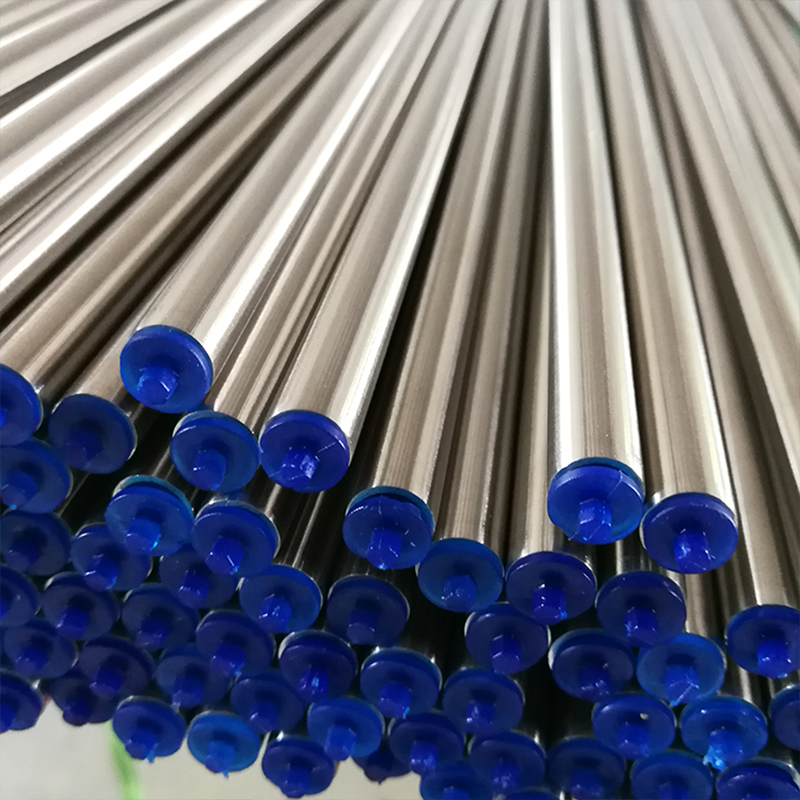

Stainless Steel Seamless Pipe

Standard: JIS

made in China

Brand Name:

Grades: 300 series/200 series/400 series, 301L, S30815, 301, 304N, 310S, S32305, 413, 2316, 316L, 441, 316, L4, 420J1, 321, 410S, 410L, 436L, 443, LH, L1 , S32304, 314, 347, 430, 309S, 304, 4, 40, 40, 40, 40, 40, 39, 304L, 405, 370, S32101, 904L, 444, 301LN, 305, 429, 304J1, 317L

Application: decoration, industry, etc.

Wire Type: ERW/Seamless

Outer diameter: 30mm

Tolerance: ±1%,

Processing type: punching, cutting

Grade: 300 series/200 series/400 series

Sectional shape: round

Alloyed or not: Non-alloyed

Invoicing: according to actual weight

Delivery time: 8-14 days

Product name: 316L stainless steel pipe seamless 1/2″ stainless steel pipe

Keyword: stainless steel pipe

Surface: satin/bright

Packing: according to customer needs

Shape: round, square, rectangular

Process: Welding/Seamless Polishing/External Polishing

Process method: polishing, cold drawing, annealing LED with nitrogen protection

Payment terms: L/CT/T (30%DEPOSIT) MOQ: 1 ton

Certification: ISO, CE

Stainless steel pipes are safe, reliable, hygienic, environmentally friendly, economical and applicable. The thin-walled pipes and the successful development of new reliable, simple and convenient connection methods give it more irreplaceable advantages for other pipes, and more and more applications in engineering , The use will become more and more popular, and the prospects are promising.

As stainless steel has many ideal properties required by building materials, it can be said to be unique among metals, and its development continues. In order to make stainless steel perform better in traditional applications, the existing types have been improved, and in order to meet the strict requirements of advanced construction applications, new stainless steels are being developed. Due to the continuous improvement of production efficiency and continuous improvement of quality, stainless steel has become one of the most cost-effective materials chosen by architects.

Stainless steel pipes can be divided into Cr series (400 series), Cr-Ni series (300 series), Cr-Mn-Ni (200 series) and precipitation hardening series (600 series) according to their composition.

200 series-chromium-nickel-manganese austenitic stainless steel 300 series-chromium-nickel austenitic stainless steel.

301—–Good ductility, used for molded products. It can also be hardened by mechanical processing. Good weldability. Abrasion resistance and fatigue strength are better than 304 stainless steel.

302—–The corrosion resistance is the same as that of 304, because the carbon content is relatively high, the strength is better.

303—–It is easier to cut than 304 by adding a small amount of sulfur and phosphorus.

304—–namely 18/8 stainless steel. The GB grade is 0Cr18Ni9. 309—Compared with 304, it has better temperature resistance.

316—–After 304, the second most widely used steel grade is mainly used in the food industry, pharmaceutical industry and surgical equipment. The addition of molybdenum makes it a special corrosion-resistant structure. Compared with 304 stainless steel pipe, it has better resistance to chloride corrosion, so it is also used as “marine steel”. SS316 is usually used in nuclear fuel recovery devices. 18/10 grade stainless steel pipe usually also meets this application level.

Model 321—Except for the addition of titanium to reduce the risk of corrosion of the material welds, other properties are similar to 304.

400 series-ferritic and martensitic stainless steel.

408—Good heat resistance, weak corrosion resistance, 11% Cr, 8% Ni.

409—the cheapest model (British and American), usually used as a car exhaust pipe, is a ferritic stainless steel (chrome steel).

410—Martensite (high-strength chromium steel), good wear resistance, poor corrosion resistance.

416—Sulfur is added to improve the processing performance of the material.

420—”Cutting tool grade” martensitic steel, similar to the earliest stainless steel such as Brinell high chromium steel. It is also used for surgical knives, which can be very bright.

430—Ferritic stainless steel, for decoration, such as car accessories. Good formability, but poor temperature resistance and corrosion resistance.

440—High-strength cutting tool steel with slightly higher carbon content. After proper heat treatment, higher yield strength can be obtained. The hardness can reach 58HRC, which is among the hardest stainless steels. The most common application example is the “razor blade”. There are three commonly used models: 440A, 440B, 440C, and 440F (easy processing type).

500 series—heat-resistant chromium alloy steel.

600 series—Martensitic precipitation hardening stainless steel pipes.

| Product name | 316L stainless steel pipe seamless 1/2″ stainless steel pipe |

| Brand | Baosteel, United Steel |

| Certificate | ISO9001, BV, SGS or according to customers. |

| Material | 200 series: 201 202 |

| 300 series:301 302 303 304 304L 309 309S 310 316 316L 321 904L | |

| 400 series:410 420 430 440 | |

| Duplex stainless:2205 2507 etc. | |

| Surface | Mirror/stain |

| Size | Based on customer’s needs |

| Standard | AISI、ASTM、GB、BS、EN、JIS、DIN |

| Application | Kitchenware, home appliances, architectural decoration, stairs, refrigerators, burner parts, automobile exhaust parts |

| Feature | Representative type of ferrite stainless steel, with magnetic |

| Good performance-price ratio and stable price | |

| Good forming ability, welding seam bending ability, high thermal conductivity, low thermal expansion | |

| Good forming ability, welding seam bending ability, high thermal conductivity, low thermal expansion | |

| Benefit | Strong corrosion and decorative effect |

| Trade terms | FOB、CFR、CIF、EXW |

| Payment terms | T/T, L/C 30% T/T advance payment at sight, and 70% of the balance will be paid after receiving the copy of B/L. |

| Cooperating shipowner | MSK、CMA、MSC、HMM、COSCO、UA、NYK、OOCL、HPL、YML、MOL |

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..