The Flooring Expert

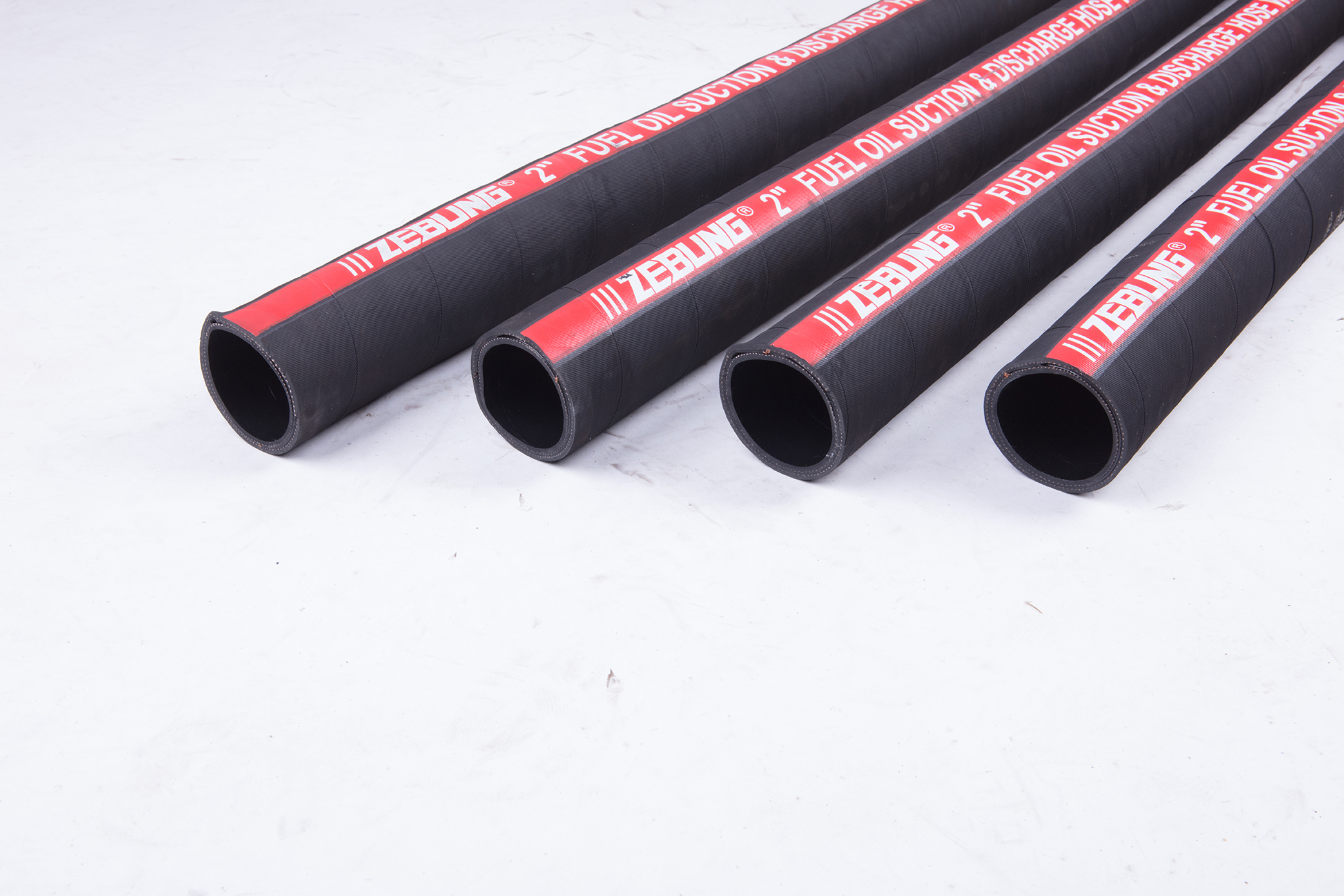

Tank Truck Hose

Tank truck oil suction hose

Construction

Tube: Black,Smooth,NBR.

Reinforcement:High tensile textile cord with helix steel wire.

Cover: Black/red/green, wrapped surface or corrugated,weather and ozone. resistant,synthetic rubber.

Safety factor:3:1.

Temperature:-30℃(-22℉)to+80℃(+176℉)

![[副本][副本][副本][副本][副本][副本][副本][副本][副本]未命名](/uploads/副本副本副本副本副本副本副本副本副本未命名.jpg)

Application

For suction and discharge of petroleum-based products,diesel,gasoline,lubricants,fuel. It withstands the vacuum, anti-static electricity,with copper wire.Tank Truck Oil hose is designed for tank tanker, rail tanker and in-plant, oilfield loading operations to transfer and transfer gasoline, oil, ethanol blends and other petroleum base products up to 50% aromatic content. It is designed for pressure, gravity flow, or full-suction service. Working pressure is a vital factor when you select the right hose for your special applications.

![[副本][副本][副本][副本][副本][副本][副本]未命名](/uploads/副本副本副本副本副本副本副本未命名2.jpg)

Characteristics

Weather and abrasion resistant cover.

Both smooth and corrugated cover available,Excellent flexibility.

For aromatic content up to 50%

|

I.D. |

O.D. |

W.P. |

B.P. |

B.R. |

Weight |

Length |

||||

|

mm |

inch |

mm |

psi |

bar |

psi |

bar |

mm |

kg/m |

ft |

m |

|

19 |

3/4″ |

30 |

150 |

10 |

450 |

30 |

100 |

0.69 |

200/130 |

61/40 |

|

25 |

1″ |

36 |

150 |

10 |

450 |

30 |

150 |

0.86 |

200/130 |

61/40 |

|

32 |

1-1/4″ |

45 |

150 |

10 |

450 |

30 |

190 |

1.23 |

200/130 |

61/40 |

|

38 |

1-1/2″ |

51 |

150 |

10 |

450 |

30 |

220 |

1.54 |

200/130 |

61/40 |

|

51 |

2″ |

64 |

150 |

10 |

450 |

30 |

300 |

1.98 |

200/130 |

61/40 |

|

64 |

2-1/2″ |

78 |

150 |

10 |

450 |

30 |

380 |

2.61 |

200/130 |

61/40 |

|

76 |

3″ |

90 |

150 |

10 |

450 |

30 |

450 |

3.16 |

200/130 |

61/40 |

|

102 |

4″ |

120 |

150 |

10 |

450 |

30 |

550 |

5.08 |

200/130 |

61/40 |

|

152 |

6″ |

171 |

150 |

10 |

450 |

30 |

750 |

8.34 |

200/130 |

61/40 |

|

203 |

8″ |

225 |

150 |

10 |

450 |

30 |

1100 |

12.71 |

100/130 |

30.5/40 |

Own film production base

The quality of film directly determines the quality of hose. Therefore, zebung has invested a lot of money to build a film production base. All hose products of zebung adopt self-produced film.

Multiple production lines to ensure production progress

Our factory has many modern production lines and a large number of experienced technical engineers. It not only has high quality production quality, but also can ensure the customer’s requirements for the supply time of products.

Each pipeline product is subject to strict inspection before leaving the factory

We have established a high-tech product and raw material testing laboratory. We have been committed to the digitization of product quality. Each product needs to go through a strict inspection process before it can leave the factory after all product data meet the requirements.

Covering the global logistics network and strict finished product packaging and delivery process

Relying on the distance advantages of Tianjin port and Qingdao port, Beijing Capital International Airport and Daxing International Airport, we have established a fast logistics network covering the world, basically covering 98% of countries and regions around the world. After the products are qualified in the off-line inspection, they will be delivered at the first time. At the same time, when our products are delivered, we have a strict packing process to ensure that the products will not cause losses due to logistics during transportation.

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..