The Flooring Expert

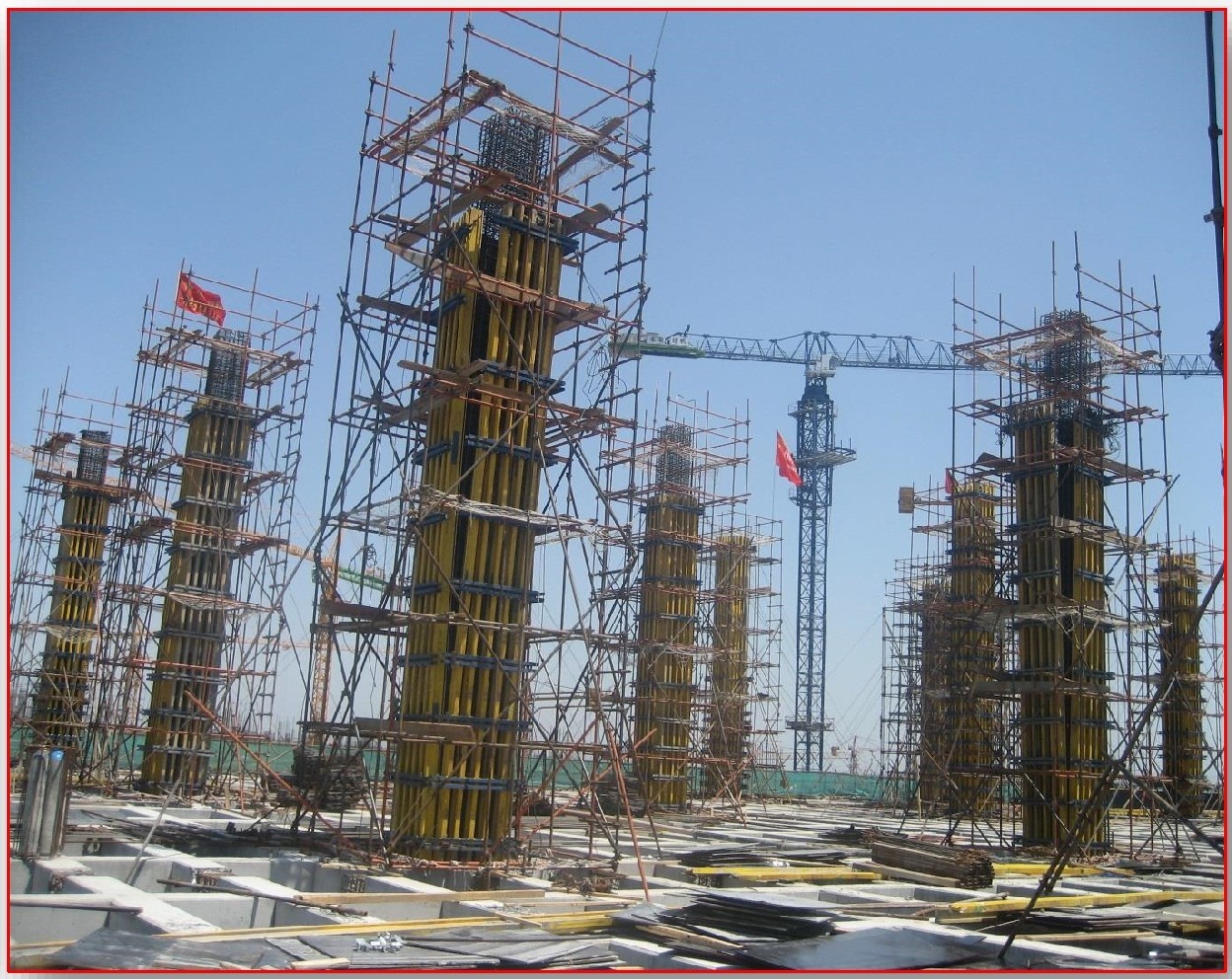

Timber Formwork System for Column

The wooden beam and column formwork is a combined formwork, which is composed of steel and wood, the wooden beam and column formwork system is composed of 18mm thick multi-layer board panels, H20 (200mm×80mm) wooden beams, backing, wooden beam connecting claws, and external corners. It is made up of spare parts such as puller, steel pin and so on. The cross-section size and height of the wooden beam and column formwork can be changed arbitrarily according to the actual project. It is flexible in use, easy to operate, light in weight, high in turnover rate, and easy to assemble. It is the first choice for engineering construction.

Features of the Sampmax Construction formwork system for column

• Strong flexibility. When the upper and lower structure layer column circumference changes, the width of the column mold can be adjusted as needed, which reflects the real quickness and convenience.

• The formwork area is large, the joints are few, the rigidity is large, the weight is light, and the bearing capacity is strong, which greatly reduces the support and expands the floor construction space.

• Convenient disassembly and assembly, flexible use, easy to assemble and disassemble on site, greatly improving the construction speed.

• Strong versatility, low cost, and high number of repeated use, thereby reducing the overall cost of the project.

• Large support columns with a height of more than 12 meters can be poured at one time, without wall screw design, suitable for difficult projects.

The construction process of the column formwork system: hoisting, moulding, vertical leveling, demoulding.

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..