The Flooring Expert

VDF Series Box way CNC Vertical Machining Center

1. SPECIFICATION

| ITEM | VDF850 | VDF1200 | VDF1500 | VDF1800 |

| Woktable Size | 1000*500mm | 1220*620mm | 1700*800mm | 2000*800mm |

| Worktable T-Slot | 5*18*100mm | 5*18*100mm | 6*18*125mm | 6*18*125mm |

| Worktable Load | 500kg | 1200kg | 2500kg | 2500kg |

| X/Y/Z-Axis Travel | 860*510*560mm | 1220*620*685mm | 1560*830*790mm | 1880*830*790mm |

| Spindle Speed | 8000pm | 6000rpm | 6000rpm | 6000rpm |

| Spindle Taper | No.40 (7:24) | No.50 (7:24) | No.50 (7:24) | No.50 (7:24) |

| Tool Magazine Capacity | 24 Bar Arm Type | 24 Bar Arm Type | 24 Bar Arm Type | 24 Bar Arm Type |

| Machine Weight | 5600kg | 8500kg | 14000 | 14500 |

| Machine Size | 2496*2530*2679mm | 2990*2621*2759mm | 4580*3250*3120mm | 5200*3250*3120mm |

2.FEATURE

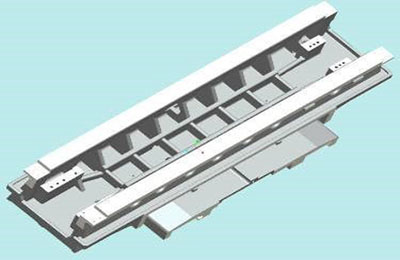

| MACHINE BED | |

|

Machine tool bed body high strength cast iron casting, casting structure after machine tool dynamics analysis and finite element analysis, reasonable collocation reinforcement structure, organization, stable, permanent to ensure quality. Ensure the basis a high rigidity. Width of machine tools bed structure, load full support of the cross slide can ensure processing heavy load capacity. |

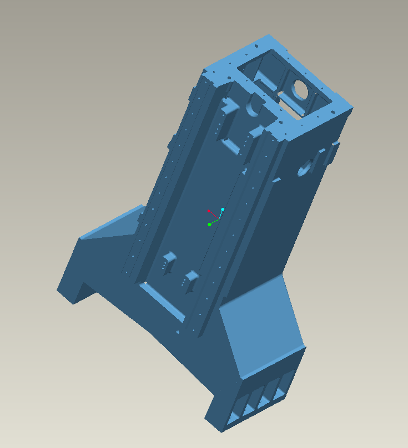

| COLUMN | |

| Machine tool column structure of large span herringbone, guarantees the high rigidity and high stability of the column, and made of high strength cast iron casting, casting structure after machine tool dynamics analysis and finite element analysis, the box cavity column with reasonable reinforcement structure, organization, stability, ensure the basic pieces of high rigidity, to ensure that the process of heavy load capacity. The slide guide of comprehensive hardening treatment, tie-in precision grinding processing, assemble the precision of satisfactory quality. |  |

| SPINDLE BOX | |

|

Spindle box structure by the finite element structural statics, dynamics analysis and topology analysis, reasonable structure design and the collocation of stiffener to ensure the high rigid box. |

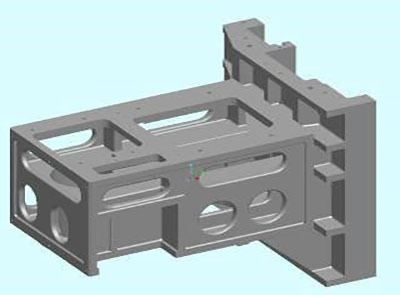

| CROSS FEED UNITS | |

| Cross slide machine tool made from high strength cast iron casting, casting structure after machine tool dynamics analysis and finite element analysis, tie-in and reasonable reinforcement, load full support of the cross slide can ensure processing heavy load capacity. |  |

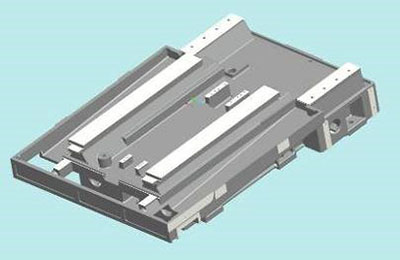

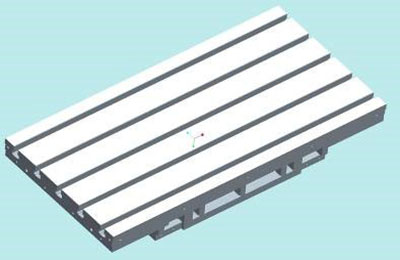

| WORKTABLE | |

|

Machine table high strength cast iron casting, casting structure after machine tool dynamics analysis and finite element analysis, tie-in and reasonable reinforcement, in the cross slide under the condition of full load support to ensure that the process of heavy load capacity. Ensure the basis a high rigidity. Workbench surface also can increase the quenching treatment, the surface hardness of HRc50 (option). |

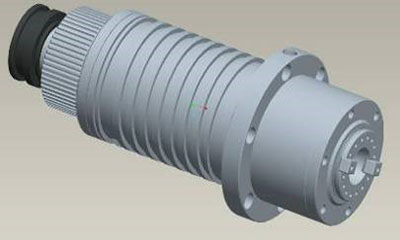

| SPINDLE | |

| High speed, high precision spindle: through high torque synchronous toothed belt drive, don’t slip, and can greatly reduce heat transmission noise and produced. Main shaft adopts precision level Angle ball bearing, the standard speed of up to 8000 r/min. High-performance spindle bearing grease lubrication, economic spindle head, cooling system, effectively control the spindle temperature rise at a high speed. Main shaft by using the IRD dynamic balance calibration equipment, direct correction spindle dynamic balance, make the spindle at high speed, avoid to produce resonance phenomenon, to ensure the best machining accuracy. |  |

| LEAD SCREW | |

|

High speed, high precision spindle: through high torque synchronous toothed belt drive, don’t slip, and can greatly reduce heat transmission noise and produced. Main shaft adopts precision level Angle ball bearing, the standard speed of up to 8000 r/min. High-performance spindle bearing grease lubrication, economic spindle head, cooling system, effectively control the spindle temperature rise at a high speed. Main shaft by using the IRD dynamic balance calibration equipment, direct correction spindle dynamic balance, make the spindle at high speed, avoid to produce resonance phenomenon, to ensure the best machining accuracy. |

| GUIDE WAY | |

| X, Y axis feed using the linear rolling guide rail support, Z axis adopt sliding guide support, high precision, good bearing performance, to ensure the positioning precision of the machine tool and repeat positioning accuracy |  |

| TOOL CHANGER | |

|

Tool changer is bamboo hat type (20 tools) ,cutter disk elective knife nearby, tool change for the pneumatic and electric control, pollution-free, easy maintenance, tool exchange fast and reliable. Knife-and-arm tool changer (special configuration): knife capacity of 24, double-arm automatic tool changer and cam tool change tool to motor drive, fast and stable. Knife sets of large capacity storage knife, motor and cylindrical cam drive and positioning mechanism, high stability. |

| MACHINE | |

| Machine is equipped with a fully enclosed shield, beautiful, safe, leak proof, protect the environment. Sealed guide shield Sino-us joint venture of choose and buy the sea Nigel Taiwan famous brand manufacturers products, effective protection guide rail and screw moving parts, prolong its service life. Spiral automatic chip removal device is concise, environmental protection, is applicable to metal and non-metallic chip conveying. Machine with manual air gun and nozzle, easy to remove iron. |  |

| CNC CONTROLLER | |

|

CNC controller system adopts the standard configuration of FANUC 0 I Mate – MD CNC system, other systems are optional. CNC system can according to customer demand for the fourth axis function, etc. |

3. ACCESSORIES

| STANDARD ACCESSORY | OPTIONAL ACCESSORY | ||

| 1 | FANUC 0i MF (5) Controller | 1 | Siemens 828D Controller |

| 2 | 24 Bar Arm Type tool magazine | 2 | 20 Bar Bamboo Type tool magazine |

| 3 | Spiral chip remover and chip storage car | 3 | X/Y/Z-Axis Guideway Protection Cover |

| 4 | One-piece safety cover | 4 | Spindle oil cooling device |

| 5 | Automatic lubrication system | 5 | Automatic measuring system for workpiece |

| 6 | Tool box | 6 | Tool break detection system |

| 7 | Working light | 7 | The 4-Axis Rotary Table |

| 8 | Warning light | ||

| 9 | Electrical box heat exchanger | ||

| 10 | Spindle air curtain dust prevention system | ||

| 11 | Spindle taper hole blower | ||

| 12 | Rigid Tapping | ||

| 13 | Workpiece cooling system | ||

| 14 | The RS – 232 interface and function of DNC | ||

| 15 | Open the door protection device (door) | ||

| 16 | Blowing dust air gun | ||

| 17 | Simple oil-water separator | ||

| 18 | Foundation bolts and block | ||

| 19 | Operation Manual, Packing List, Certificate of Quality | ||

4. APPLICATION

5. PACKING AND DELIVERY

Write your message here and send it to us

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..