The Flooring Expert

Water Based Adhesive For Hardwood Woodworking

The two-component jigsaw glue is developed for the characteristics of wood material and the characteristics of large deformation due to absorption and loss of water. It can penetrate into the wood well, and the glue has excellent film formation and strong cohesion, especially it can react with the characteristics of wood fibers. The group forms a good chemical bond, which solves the problem of easy cracking of the wood panel. Elm wood is tough, with clear texture, moderate hardness and strength, and can be adapted to general open-carved reliefs. The planed surface is smooth, the string surface pattern is beautiful, and the “wenge wood” pattern is one of the main furniture materials. The characteristics of its wood, the heartwood and sapwood are clearly distinguished, the sapwood is narrow and dark yellow, the heartwood is dark purple-gray; the material is lighter and harder, the mechanical strength is higher, the grain is straight, and the structure is thick. It can be used for furniture, decoration, etc. The elm wood can be dried, shaped, carved, polished and painted to make exquisite carved lacquer crafts.

Applicable Material

Red oak

White oak

China ash

Walnut

Chinese oak

Acacia wood

Ebony Wood

Ash wood

Hardwoods are mostly derived from deciduous fine-leaf forest trees, including oak, mahogany and birch, red oak, hard maple, rye, beech, boxwood, etc. Usually the price is higher, but the quality is relatively better than cork. Hardwood (hardwood) is broad-leaved wood, which refers to the wood produced by the trees of the angiosperm phylum. Hardwoods are in contrast to conifers, also known as softwoods. Hardwoods are generally denser and harder, but the real hardness of hardwoods and softwoods are very different. There are many varieties that overlap each other. Sometimes hardwoods (such as balsa) are softer than most softwoods. Hardwood is generally used to make exposed products such as furniture, wooden floors or utensils. In areas where softwood is lacking, such as Australia, hardwood is even used as a structural material for construction.

Applicable Machine

Manual fixture

Four-sided flip jigsaw machine

A-shaped jigsaw machine

Fan blade rotating jigsaw machine

Product features

Quick dry

The active period is short, the drying speed is fast, and it is suitable for high-frequency and automatic line technology.

High bond strength

The initial adhesion is good, and the bonded material will break 100% in 24 hours.

Easy to paint

The glue that has been mixed with the main solid foams, the glue has passed the active period, and the fluidity can be restored after stirring.

Low price over the same period

The cost is lower than most products on the market under the same quality conditions, and the quality of the same grade glue is higher than most products on the market.

Operation Specification

Flatness standard: ±0.1mm, moisture content standard: 8%-12%.

The main agent (white) and curing agent (dark brown) are mixed according to the corresponding ratio 100:8 100:10 100:12 100:15

Use a stirrer to repeatedly pick up the colloid 3-5 times, and there is no filamentous brown liquid. The mixed glue should be used up within 30-60 minutes

Gluing should be completed within 1 minute, the glue should be uniform and the end glue should be sufficient.

The glued board should be pressed within 1 minute, and must be pressurized within 3 minutes, the pressing time is 45-120 minutes, and the extra hardwood is 2-4 hours.

Pressure: softwood 500-1000kg/m², hardwood 800-1500kg/m²

The curing temperature is above 20℃, light processing (saw, planing) after 24 hours, and deep processing after 72 hours. Avoid sunlight and rain during this period.

A clean glue applicator can ensure that the glue is not easy to block, otherwise it will affect the amount and uniformity of the glue.

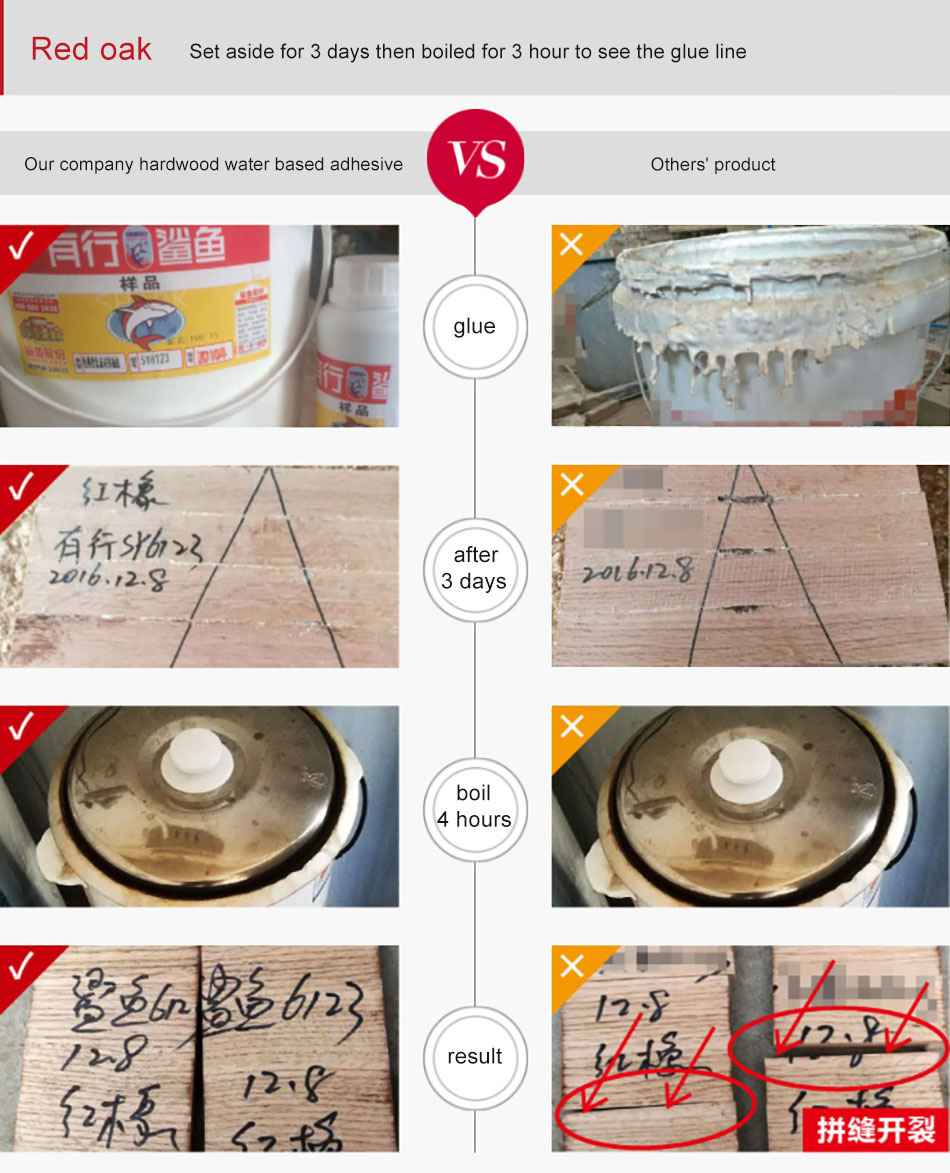

Test Contrast

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..