The Flooring Expert

Water Based Adhesive For Medium Hardwood Woodworking

The two-component jigsaw glue is developed for the characteristics of wood material and the characteristics of large deformation due to absorption and loss of water. It can penetrate into the wood well, and the glue has excellent film formation and strong cohesion, especially it can react with the characteristics of wood fibers. The group forms a good chemical bond, which solves the problem of easy cracking of the wood panel.Solid wood panels are durable and have natural textures. Most of them have the unique fragrance of natural wood, have good moisture absorption and air permeability, are good for human health, and do not cause environmental pollution. They are high-quality panels for making high-end furniture and decorating houses. Some solid wood panels of special materials (such as beech) are also ideal materials for making gunstocks and precision instruments.

Applicable Material

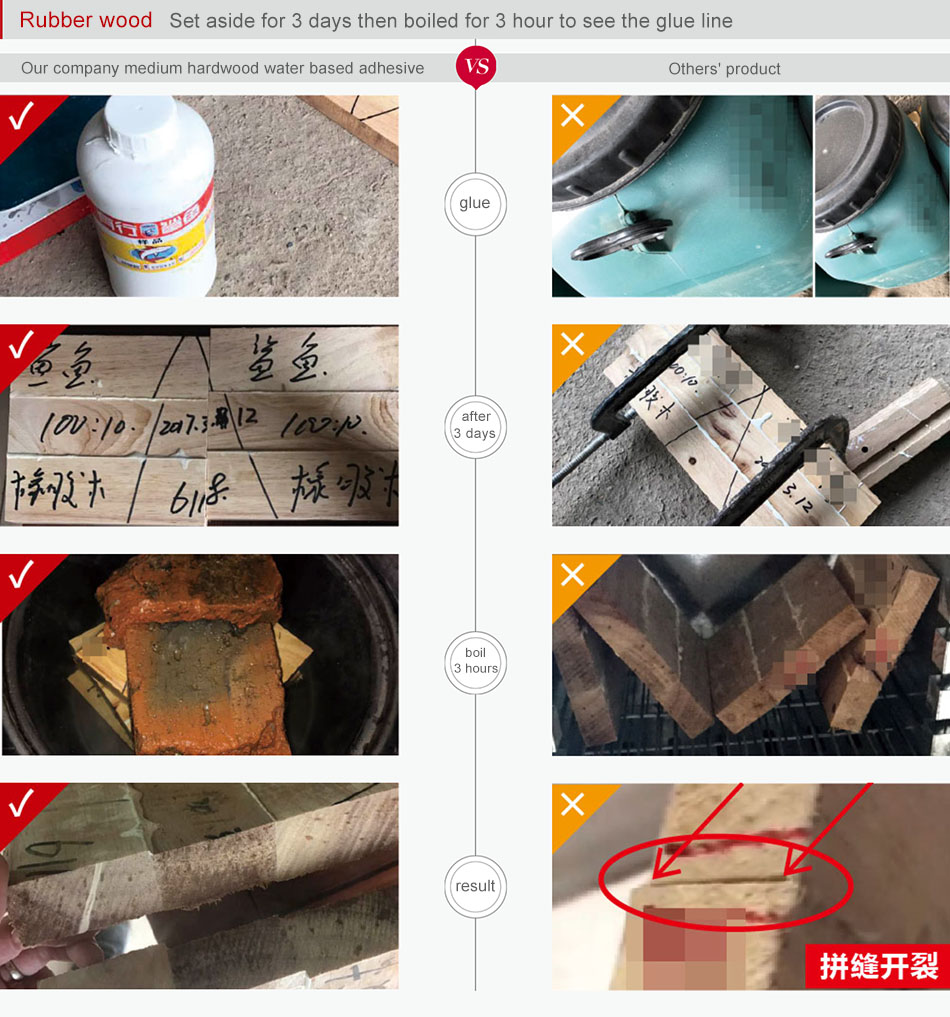

Rubber wood

Chinese Mahogany

Birch

Elm

Cypress

Eucalyptus wood

Cryptomeria

Basswood

In recent years, with the development of the domestic economy, solid wood furniture has become more and more popular among consumers, because solid wood furniture has obvious advantages compared with other materials. In particular, many high-end furniture are made of solid wood, which is strong, durable, environmentally friendly, and environmentally friendly. The wood of birch is light brown to reddish brown, with a shiny surface and a smooth mechanism. Yellow and white with slightly brown, obvious annual rings, pure wood body, slightly heavier and harder, fine structure, high mechanical strength, elasticity, high moisture absorption, dry and easy to crack and warp. It is not very durable under the environment that is prone to decay, and is more used in the form of splints. Birch is usually used for special plywood, flooring, furniture, pulp, interior decoration materials, vehicle and ship equipment, plywood, etc. The furniture is smooth and wear-resistant, with clear patterns. It is now used in the production of structures, parquet and interior frames.

Applicable Machine

Manual fixture

Four-sided flip jigsaw machine

A-shaped jigsaw machine

Fan blade rotating jigsaw machine

Product features

Quick dry

It is suitable for high-frequency machines, fully automatic splicing machine technology, and unlimited weather.

High bond strength

The initial adhesion is good, and the bonded material will break 100% in 24 hours.

Easy to paint

The glue that has been mixed with the main solid foams, the glue has passed the active period, and the fluidity can be restored after stirring

Low price over the same period

The cost is lower than most products on the market under the same quality conditions, and the quality of the same grade glue is higher than most products on the market.

Operation Specification

Flatness standard: ±0.1mm, moisture content standard: 8%-12%.

The main agent (white) and curing agent (dark brown) are mixed according to the corresponding ratio 100:8 100:10 100:12 100:15

Use a stirrer to repeatedly pick up the colloid 3-5 times, and there is no filamentous brown liquid. The mixed glue should be used up within 30-60 minutes

Gluing should be completed within 1 minute, the glue should be uniform and the end glue should be sufficient.

The glued board should be pressed within 1 minute, and must be pressurized within 3 minutes, the pressing time is 45-120 minutes, and the extra hardwood is 2-4 hours.

Pressure: softwood 500-1000kg/m², hardwood 800-1500kg/m²

The curing temperature is above 20℃, light processing (saw, planing) after 24 hours, and deep processing after 72 hours. Avoid sunlight and rain during this period.

A clean glue applicator can ensure that the glue is not easy to block, otherwise it will affect the amount and uniformity of the glue.

Test Contrast

Products categories

WHY CHOOSE US

Since its establishment, our factory has been developing first world class products with adhering the principle

of quality first. Our products have gained excellent reputation in the industry and valuabletrusty among new and old customers..